Description

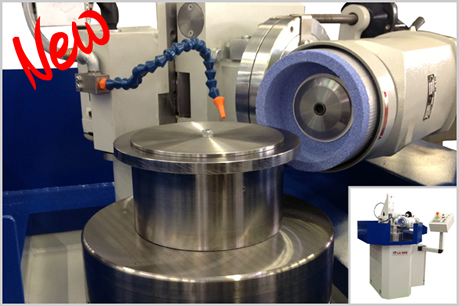

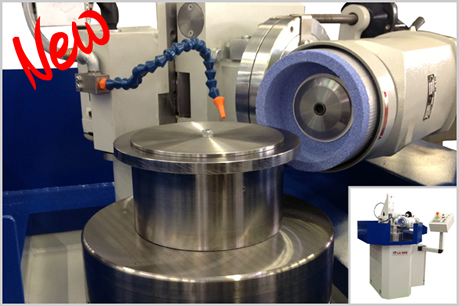

- Universal Rotary Surface Grinder with Vertical Spindle and rotating chuck

- Surface Grinding of a wide range of parts including carbide inserts, dies, punches, etc.

- Strong tower with tilting motor allows grinding of bevel angle on circular knives

- Automatic downfeed adjustable per pass and in total as well as time in between downfeeds

- Ability to repeat position for centering bevel angle on double bevel circular knives

- Ability to use CBN and Diamond as well as Oxide Wheels or Segments

MVM LA 500 Automatic Rotary Surface Grinder with Tilting Head & Vertical Spindle

Standard Machine Grinding

- 3.5HP motor

- Heavy Duty flood coolant system

- 300mm diameter Chuck with fixed rotation of 30RPM

- Automatic Grinding cycle with speakout timer

MVM LA 500 Optional Accessories

LA 500 with Mag Chuck + Flange set (left) - LA 500 without Mag Chuck (right)

Chuck Enhancement Options

Optional 90 Degree Tilt for O>D> Grinding Metalworking Slitters

PLC Control Option offers:

Meat Slicer Blade Attachment Option:

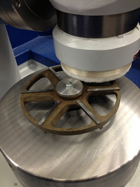

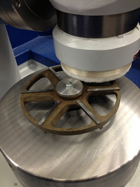

Gang Bottom Slitter Grinding Option:

Using a 15v9 wheel allows user to grind each row of a gang slitter at negative 5 degree.

Coolant System Options:

- Upgrade to 5.5HP Grinding Motor

- Added Column Height increases chuck to wheel clearance to 12"

- 150mm Segment Holding Ring (upgrade to 5.5HP recommended) (allows use of grinding Segments instead of cup wheels)

- Flange Set for grinding circular knives (16mm center)

- 90 degree head tilt for flat grinding side of round parts

LA 500 with Mag Chuck + Flange set (left) - LA 500 without Mag Chuck (right)

Chuck Enhancement Options

- Magnetic Chuck (300, 350, or 400 mm)

- Tilting attachment for punch sharpening (Similar to the Amada device)

- Variable Rotation speed of the Chuck (From 3 to 30 RPM)

- Meat Slicer blade attachement

Optional 90 Degree Tilt for O>D> Grinding Metalworking Slitters

PLC Control Option offers:

- Fast wheel approach during setup

- Timed sparkout cycles for fine finishing

- Automatic wheel lift off and machine shut down at end of cycle for energy conservation and quick setup from blade to blade

Meat Slicer Blade Attachment Option:

Gang Bottom Slitter Grinding Option:

Using a 15v9 wheel allows user to grind each row of a gang slitter at negative 5 degree.

Coolant System Options:

- Magnetic Coolant cleaner with rotating disc and External coolant tank

- Mist Extraction System

Maximum Part Diameter: 500mm (20”) or 700mm (28")

Mag Chuck to Wheel Clearance: 80mm (3-1/8”) (12” optional)

Clearance without the Mag Chuck: 140mm (5-1/2”) (12” optional)

Grinding Motor: 3.5HP (5.5HP Option)

Grinding Wheel Specs: 150mm dia x 20mm bore

Voltage: 220V, 3phase, 60Hzor 440v factory only

Shipping Weight: from 770lbs to 1800 lbs

Mag Chuck to Wheel Clearance: 80mm (3-1/8”) (12” optional)

Clearance without the Mag Chuck: 140mm (5-1/2”) (12” optional)

Grinding Motor: 3.5HP (5.5HP Option)

Grinding Wheel Specs: 150mm dia x 20mm bore

Voltage: 220V, 3phase, 60Hzor 440v factory only

Shipping Weight: from 770lbs to 1800 lbs

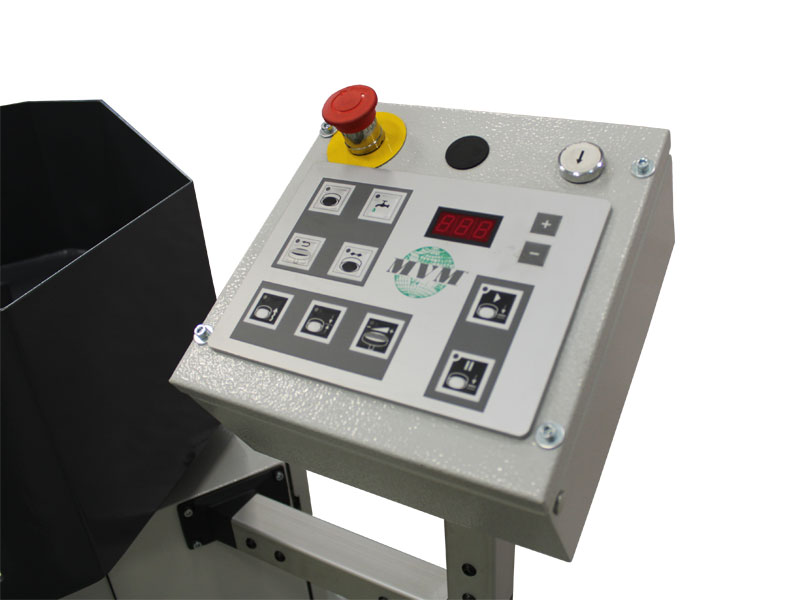

Optional PLC