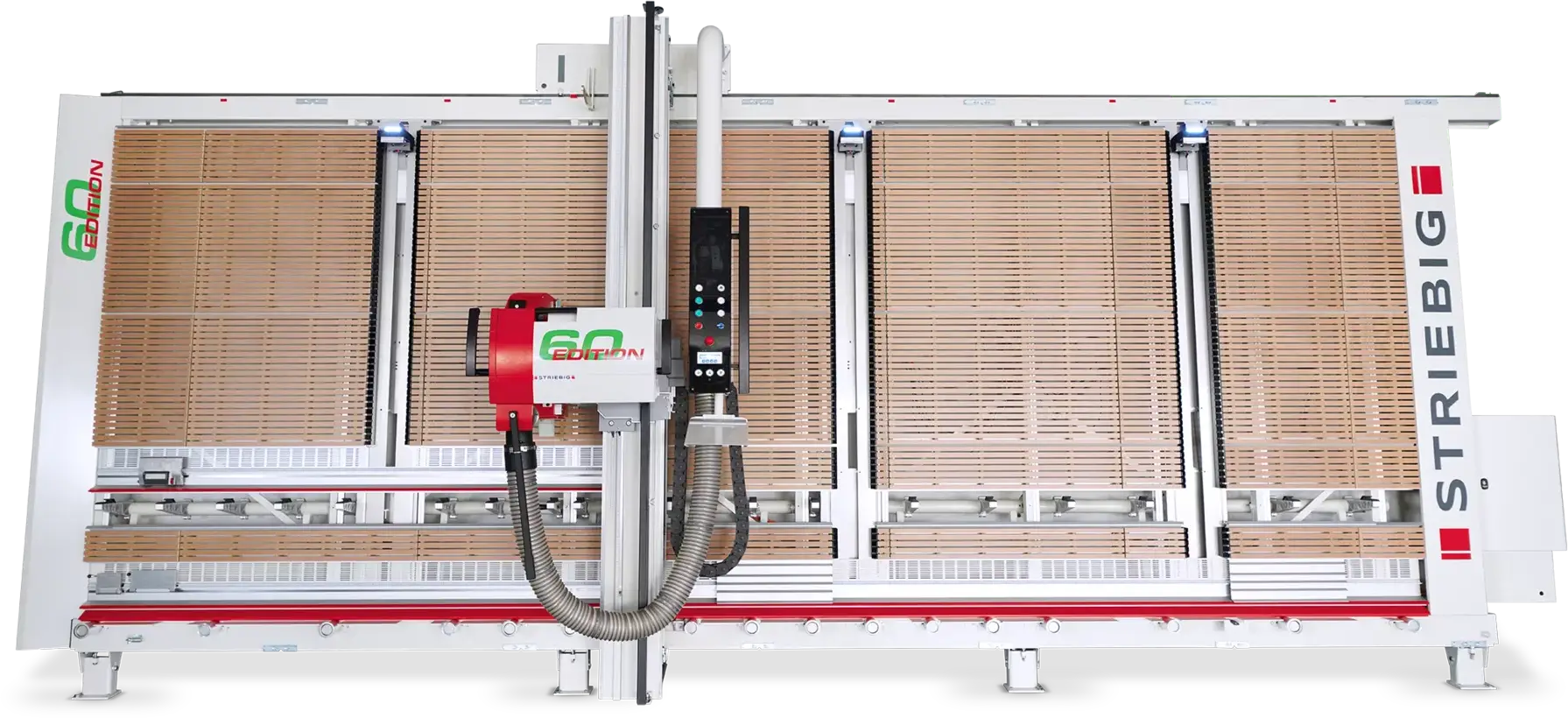

Edition 60

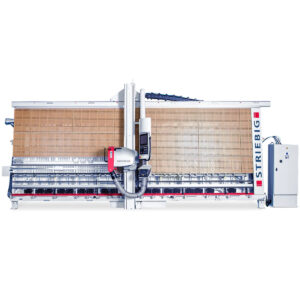

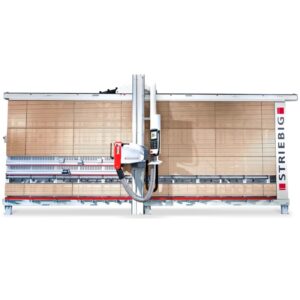

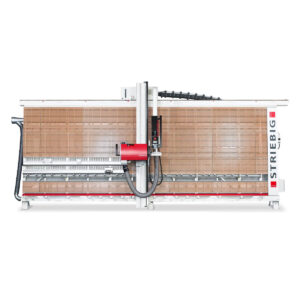

The vertical panel saw that does the heavy lifting.

All of the features of the Striebig Standard S, plus

- 2 (or 3) panel lifters with 176 lb. capacity each

- Full wood support wall for added dust control

- Digital measuring w/ fine adjust in X & Y axes

- 7’ x 17’ cut capacity

- Comfort package with auto-locking rollers, carriage clamp, and laser

Product Details

The Edition 60 panel saw is a full-size, fully-loaded Standard S machine PLUS panel lifters (lowering units) that allow for easy one-person panel processing. Though the saw travel is manual, there is little or no need to remove or reload parts of a sheet in order to cut them to finish size. You process the sheet from the bottom. Trim cut the bottom of the sheet, cut a strip, then process that strip into finish cut parts while the rest of the sheet suspended by the lifters. After that strip is finished, cut the next strip and so on…

- Truly a one-person machine

- No need to flip the panel

- No need to remove partial sheets and then reload them for finish cutting

- No concern of the top of the panel binding the saw blade

- 30% faster than a manual STRIEBIG without lifters

Strong and compact panel lifting device (PAV)

The integrated EDITION 60 comes standard with two panel lifters that can be used for panel materials up to 10ft × 7ft and up to 350lbs (175lbs each). With an additional lifter (optional), panels up to 16ft x 7ft and weight up to 525lbs can be processed.

Advanced Standard Features

- Wood support wall with integrated small parts support

- Panel lowering device (PAV) with two panel lowering units

- Pneumatic clamping of the motor carriage

- Pneumatic auto-locking support rollers

- Digital measuring system DMS-Y, incl. fine adjustment

- Digital measuring system DMS-X, incl. fine adjustment

- Laser-line to show placement of horizontal cut

Clear push-button control for easy operation

The EDITION 60 is operated by means of clear push-button controls. The panel lifting device can be moved quickly and precisely. The LED lights on the panel lifting units guide the operator safely through the sawing process.

Pre-Install Checklist

All Striebig saws require 3-phase, 60Hz power. Power comes to the Striebig from a customer-supplied disconnect into the overload/main switch box on the right side of the saw- either to a small box mounted to the side of the frame or to a floor-mounted control box, depending on the model. It is the responsibility of the customer to get power from the disconnect to the main switch/overload box, ideally during installation, but power must be to the disconnect before the technician arrives to install the machine!

If 3-phase power is unavailable, a rotary-type phase converter can be used. It should be a high-quality converter with integral voltage stabilization and should be approx. 2x the hp rating of the Striebig (e.g. a 10hp converter for a Compact and a 15hp for a Standard or Control)

- Compacts: 208V or 240V, 20A circuit; 440V or 480V, 10A circuit

- Standard, Standard S, Edition 60, Evolution, Control, 4D: 220V, 30A circuit

- (Standard, Standard S, Edition 60 only): 440V, 15A circuit

- Control with 4SB bottom trimming option 220V, 40A circuit.

Standard S, Edition 60, Evolution, Control, 4D and Standard models with optional auto-locking rollers all require air at a 90psi (6 bar) minimum. Striebigs do not consume a great volume of air but do require pressure. An air dryer is highly recommended as any moisture in the air is harmful to the machine! Connection will be on the ride side of the machine.

All Striebigs require connection to a dust collector. It can be a dedicated stationary unit or a large central unit, but sufficient dust collection is critical to the optimal performance of the saw.

Compacts have two separate 4” ports. The main connection can be oriented to either end of the frame and is at about 5’ from the floor. Connection to the port at the bottom right of the frame is elective, but each connection should have 500cfm for wood dust.

All other models have a single 5-1/2” (140mm) port that can be oriented to either end of the frame. That connection should have 1000cfm.

More detailed specifications, including air speed, pressure, and volume, can be provided by our technical department.

Since all Striebig saws are bolted to the floor, the floor must be rigid and capable of being drilled.

- It is preferable to avoid spanning over cracks or expansion joints, but it is not critical if this cannot be avoided.

- Wood floors require adequate support with minimal flexibility.

- If there is radiant heat in the floor, it is the customer's responsibility to determine where it is safe to drill.

- The maximum floor pitch from one end of the machine to the other is 1-1/4”. Special parts or machining to compensate for more pitch than this is the customer's responsibility.

Striebig FAQs

Striebigs can be as small as 70 sq. ft. (Compact) or as large (in the largest standard frame sizes) as 134 sq. ft. Besides the space that the machine occupies, you need room to load, operate, and unload the machine. That will depend on the size of the sheets you are cutting and how you are storing and bringing them to and onto the saw. Generally you will want more room to the right side of the saw for loading full sheets, and less room is required to the left where you will be off-loading finish cut pieces.

Yes, with the Striebig expert cut optimizing allows you can go screen to machine on a Control or Striebig 4D

All Striebig machines have dust hose (and pipe) to get the dust from the saw head to the back of the machine. All machines prior to 1993 had fans inside the housing to propel dust into a dust bag, so a collector was not required. From 2005 on all models require a dust collector, but are much more efficient in their dust pick-up. All Standard III, Automat III, Compacts, Evolution and Control models require collectors. Standard II models up to 2005 do not require them, but Standard TRK models from 2005 on do. Compacts have 4” diameter ports (Compacts after 2004 have a second optional 4” port on the bottom right of the frame) and require 500cfm/port for wood dust. All others models have either single 160mm or 140mm ports (depending on year) or can be connected to two 4” ports, and generally require 1000 cfm. You may contact us at Colonial Saw for more detailed specs regarding speed, pressure, etc.

Most Striebig models do not require air, however, a Compact Automatic, Evolution, Control, and a Standard TRK with the optional pneumatic locking rollers do. They do not consume much volume, but would require a supply of 100 psi min. The air controls such things as the locking rollers, and the locking of the saw beam and pivoting of the saw head on the Evolution and Control. The critical function of shifting the grid so the saw blade does not cut into it, is a mechanical system on all models and does not use air.

A Compact or current Compact Plus can fit under an 8’ ceiling. They are 7’ 10-1/2” at the highest point, except for the repeat rip device scale, which extends to 8’ 6” high when the saw head is all the way to the top. If this is an issue, then you can choose the smaller repeat rip device, which will keep it within the 7’ 10-1/2”, or physically limit the height to which you bring the saw head, if you only cut 4’ material. A Standard model (of _168 frame height) has a height of only 7’8” and an Evolution or Control (also of _168 frame height) is 8’ 1-1/2”.

The answer has two parts:

- A riving knife behind the saw blade prevents the board from pinching.

- As the saw cuts from left to right, the operator, positioned behind or to the left, can manage the top piece with the left hand or both hands if it's an automatic saw. For small pieces (up to 12”), they hold it from the top or press it against the back support as the saw exits to the right. For larger pieces, like a 4’x8’ board, they insert a wood wedge from the tool kit into the saw kerf past the halfway point to act as a fulcrum, opening the cut as the saw finishes.

Yes! Stack-cutting is a nice advantage of a vertical panel saw over a table saw or slider. Compacts can handle up to 2-3/8” of material or 3 sheets of ¾”. All other Striebigs have a 3-1/8” depth of cut or 4 sheets of ¾” material capacity! An Evolution or Control can be special-ordered to go up to 4” depth, and the new 4D model can go up to 5” depth! In the real world, we mostly see up to two sheets at a time cut on Compacts and maybe three sheets on the other models. Material handling can become more the issue than the saw’s ability to cut it. What is more common is to start with a single sheet, but then once it has been cut into more manageable pieces, then those pieces are put back on the saw 2 or 3 at a time and cut into like parts, like the two sides of a cabinet. This can add up to a lot of time savings over a table saw or slider!

Gravity! The panel rests on either the support rollers on the bottom or the center shelf fingers, if it is smaller. The saw frame is leaning back at a 5-degree angle, so the piece just sits there nicely. There is a little bit of spring tension in the shroud (guard) that covers the blade to help hold the material and dampen vibration. In terms of right to left movement, friction holds the piece in place on the center shelf. The rollers on the bottom of a Compact have a flip-up panel stop on the right side to keep the panel from rolling away as you make a horizontal rip cut. On a Standard model there are foot-pedal operated locking rollers (factory option on Compacts), and on Compact Automatics, Evolution, and Control models the rollers lock automatically (pneumatically) during a cut (optional upgrade on Standard TRKs).

Yes! Since Ludwig Striebig invented his machine in the late ‘50s, Striebig has always been focused on the finish cut and cut quality. Some materials, including melamines, developed in the last 30 years have more sensitive coatings and therefore require scoring on one side in order to have a good clean cut on both sides of the sheet. There are two methods of scoring employed on most Striebig models. Over 20 years ago, Striebig developed its first true scoring saw unit, and has continued to develop and improve this concept to this day. They are belt-driven units that use split-blade type scoring saw blades. The two blades are adjusted for width either with shims in its simplest version, or by the simple turn of the T-handle Allen wrench in the advanced adjustable (“Quick-set”) version. This blade is even available in diamond for extra-long life. These scoring saw units are available on all Striebig models except the Standard TRK. Striebig has never entertained the idea of scoring panels with an inexpensive, “scratch-knife” type of scoring that others employ. These systems simple do not work very well on a wide variety of materials, and you never see them used on other types of saws, like sliding table saws or beam saws, so…

The other method of scoring widely used on Striebig saws without the optional scoring saw, is the back-scoring or climb-cut scoring method, where the main blade is used to score the panel. On a vertical panel saw, the side of the panel that is up against the backing grid is the side that will get the reliably good finish cut (like the top side when you’re using a table saw). It’s the side you’re looking at that is the side that needs scoring. When you use the back-scoring method for a vertical cut, you start with the saw head at the bottom. You plunge in until the saw blade just touches the panel (the riving knife can serve very nicely as a depth stop in this position- the blade is just a bit deeper than the riving knife), and you bring the saw head up to the top of the panel. You see the score mark right in front of you. At the top of the panel you plunge the saw to full depth and make your normal separating cut to the bottom. But then just leave the saw at the bottom, so you can start your next cut. You’ve completed one cut cycle. You’ve just started and ended the cycle in a different place. It’s the same amount of work! And the same blade that did the scoring did the cutting, so there are no alignment issues- simple! The same concept applies to horizontal cuts. When you have to score enough panels, or are using an automatic saw, a scoring saw unit will pay for itself in reduced saw sharpening bills.

The tallest panel will depend on your frame size. A Compact, manual or automatic, can fit a 65” tall panel. Taller Compacts can handle up to 81.5” or 86.5” tall panels. All other models can handle similar height panels for the standard height machines, but can also be special-ordered to handle panels up to 9’ or 10’ tall!! In terms of length, without having to roll a panel through the saw, (which is a possibility on a Striebig, because of the heavy-duty, precision rollers), you can cut up to 10’2”, 15’1”, or 17’6” on Compact models. On all other Striebigs, you can cut 10’10”, 14’1” or 17’4” on standard frames, but they can be special-ordered to cut 20’8”, 24’, 30’6” or even up to 50’!!!

That is a tricky question that we get regularly and needs further definition. If you are asking what the smallest piece you can start with and cut down further, the official traditional answer is 8” x 20”. But these days with the built-in wood small parts support area on Compacts (optional on Standard TRKs) and full wood support area on Evolution and Control, the origin piece can be far shorter in height than 8”, probably as little as 1” tall. Also, all of the machines now have center shelf fingers that can be repositioned along the center shelf bar. You should have at least two fingers supporting at least one side of a vertical cut, so approximately 4-6”. The shroud will only allow you to get so close to the support surface for a horizontal rip cut. On a Compact or Standard, that is about 1-1/4”. On an Evolution or Control, that is about 2-3/8”.

With proper care and maintenance, a Striebig vertical panels saw can last for decades.

All Striebig machines are 3-phase, but many shops run them perfectly with a rotary-type phase converter, which converts 220V single-phase power to 240V 3-phase power. There are several manufacturers of quality phase converters, but make sure you select a reputable one. They can usually run up to three machines, as long as you start the largest horsepower machine first. You will need to size the phase converter at a minimum of 1-1/2 to 2 times the horsepower of the machine, so a Compact or an old Econom would require a 7.5hp minimum converter, but 10hp is recommended. All other Striebigs should run on 15hp converters.

In almost all cases, no. Unless you are already intimately familiar with the use of vertical panel saws and have moved, re-installed, squared, and calibrated your previous Striebig more than once, we strongly do not recommend trying to install a new Striebig yourself. It should be done by a certified Striebig dealer technician or Colonial Saw. Besides the proper assembly, squaring confirmation, and calibration, a certified installation technician will train you on the proper use of the machine and its accessories, and maintenance of your machine. That alone can be worth many hours of reading the operating manual and then trying to relay that information to others, not to mention the possible wear or damage to your machine without this information.

You can order parts from your local Striebig dealer. If you do not have a relationship with your local Striebig dealer, you may contact Colonial Saw and order parts with a credit card, if you do not already have an account. We stock most parts for all Striebig models going back 30+ years. It is important to have your Striebig saw information, such as model, “type” (which is actually the frame size), serial # (usually 5 digits starting with 1-4), and year of construction (mo.yr). This information should be on a nameplate that is on the carriage (the part that goes up and down the beam and holds the saw head). Only on very old saws is this nameplate on the motor itself.

Every new Striebig machine is warranted against defective parts, including electrical components, for a period of one year from the date of service, including parts and labor. But you need to contact your local Striebig dealer or Colonial Saw for approval to insure that the part in question is covered under warranty before returning it or ordering a replacement part.

Most options are retrofittable- Except grooving/dadoing but varies by saw model.

A manual Striebig saw, like a Compact, is going to be about 3-4 times as efficient as cutting sheets on a table saw, so add up the time you take cutting it that way and divide by 3 or 4. If you spend 10 hrs./week to cut parts on a table saw, on a Striebig it will take about 3 hrs. That saves 7 hrs./week. If the cost of those hours is $18/hr., all in, then that is $126 savings/week, or (x 4.3 weeks/month) $546, which is about the lease payment on a Compact including delivery and installation (depending on location). Not only do you gain efficiency to cover the cost, you are working safer, saving space, getting much better cut quality and square parts, which reduce downstream processing time.

Saw blades are designed specifically for different materials and applications. You do not want to use the same blade to cut particle board core melamine that you use for solid surface. You do not have to buy blades from us, but we do stick blades for various applications. The blade that comes included with every Striebig saw from the start is a hollow-face blade that is very good for cutting melamine and veneer plys with a nice clean, crisp edge. It has a concave face to the tooth which produces a sharp point on the upper corners of the teeth. Not every sharpener has the equipment to sharpen this blade properly. We have a partial list of those sharpeners on the website. But we also have available a premium HATB (high alternate top bevel) blade to cut more delicate melamines and veneers. If you cut solid surface or aluminum, there are blades specific to those materials that have more teeth in a TCG (triple chip grind) configuration with a negative rake/hook angle (teeth are leaning back). Many people prefer an ATB (alternate top bevel) blade for cutting veneer plys, because they are more readily sharpened by local shops, do a nice job, and may be less expensive. TCG blades with a moderate number of teeth and positive hook are good for general purpose cutting and long life. There are also blades specifically for ripping solid stock that have very few teeth. And we also stock blades that are specifically designed for plastics- one that is designed for hard plastics like acrylics, with more TCG teeth, and one for soft plastics like nylon and polypropylene, with much fewer ATB teeth.

Routine maintenance is important for any machine, and even a Striebig requires some, albeit not very much. The first job is to remove the offcut pieces/scraps from within and around the saw. After that, the single most important piece of maintenance is to oil the machined guideways on which the saws travels. Just pour a little 20W motor oil on a rag and once/week wipe the top rail of the frame and the three sets of guideways on the beam. Do not worry about oil attracting dust! The wipers/scrapers that are around each bearing wipe the surface clean, so the bearings roll smoothly. Oiling the ways protects the bare steel and allows those wipers to glide smoothly along the rails and not jump and jitter (and potentially roll under a bearing) along the way. While you have the oily rag in hand, it’s good to also wipe the round column that the saw head plunges in and out on, and the plate that the parallel guides act on. Next, there are two grease points for the slide ball bushings use to plunge the saw head on that the round column. The grease gun for these fittings is included in the tool kit. Wipe the fittings and pump one shot of grease into each fitting once/month. Beyond that, all the bearings are sealed and don’t require maintenance. There is no lubrication for the shifting grid; no lubrication for the counterweight cables or the center shelf bar. Every so often you should make a visual check of the wipers and make sure they are all in place and in good condition. On models with an air supply, you will need to check the water reservoir and drain any water that may be collected there. If you do these few basic things your Striebig will run well for more than 30 years, as many still are!

Striebig Maintenance

View our recommended maintenance schedule

Striebig Troubleshooting

View our technical resources for Striebig owners