UT.MA AF801

CNC Automatic Dual Side

CNC programmable double-side grinder with 3-axis CNC controlled grinding, AC servo motors, interpolation for straight and form or profile grinding, automatic electronic indexing system, hydraulic saw blade clamping & saw carrier locking, plus menu-driven programming with memory for fast setup.

Product Details

Description

- 5-axis CNC controlled grinding with AC servo motors

- 3-axis interpolation for straight and form or curved tooth side grinding

- Oscillation and multipass grinding

- Automatic Electronic Indexing system

- New style touchscreen

- Menu-driven programming with memory for fast setup

Standard Program Capability:

- No lift-off, straight up/down

- Lift-off, move away at bottom of tip

- Reverse lift-off, infeed at bottom of tip

- Multi-pass with micro infeed (thin kerf)

- Conical grind (scoring saws)

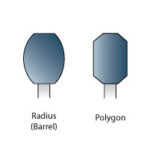

- Radius & Polygon grind (barrel grind)

- Top/bottom chamfer grind

- Alternated side grind (ex. Alternating flush to plate)

- Cutters (ex. groovers, shapers)

Features & Benefits

Specifications

Accessories

Parts, service, and support for your grinding machine.

We’re here to help in whatever way works best for you: on-site, over the phone, or remotely through Zoom, Teams, WhatsApp, or FaceTime.

Colonial Saw's support team is available 8:00 a.m.—8:00 p.m. EST.