Swift CNC Precision in Woodworking Automation

P-System CNC offers swift efficiency and precision when crafting required P-System connector slots without the manual intervention of traditional handheld tools. The logical choice for scenarios requiring industrial production with P-System-connected furniture components, P-System CNC integrates seamlessly with PNC routers to ensure seamless integration with contemporary CNC machinery for error-free setup and immediate mass production.

The P-System CNC revolutionizes woodworking by mass-producing P-System grooves with unparalleled speed and production efficiency. Rapid CNC machining achieves uniform cuts across material sheets, guaranteeing precision and high-speed wood shaping.

Integrated seamlessly with advanced CNC tooling, automation, and software, the system tailors precise grooves to project specifications, exceeding the capabilities of traditional hand tools like the Zeta P2 and enhancing productivity and quality in woodworking operations at any level.

Modern Advantages of the P-System CNC

Integrating P-System advantages into CNC production is widespread, with numerous companies globally adopting the system on their CNC routers. Macros facilitate swift integration into new machines while existing products are adapted seamlessly. Swiveling aggregate heads also enable P-System grooves to be cut at various angles, facilitating versatile joint configurations.

The efficient creation of detachable joints, whether through clamping or gluing miters or butt joints, also underscores the versatility of the P-System. Integration with vertical machining centers, manufacturers, and software providers offers expedited groove creation, while compatibility with various CNC machining philosophies ensures adaptability to diverse production setups.

P-System CNC Technical Requirements

Equipment Requirements

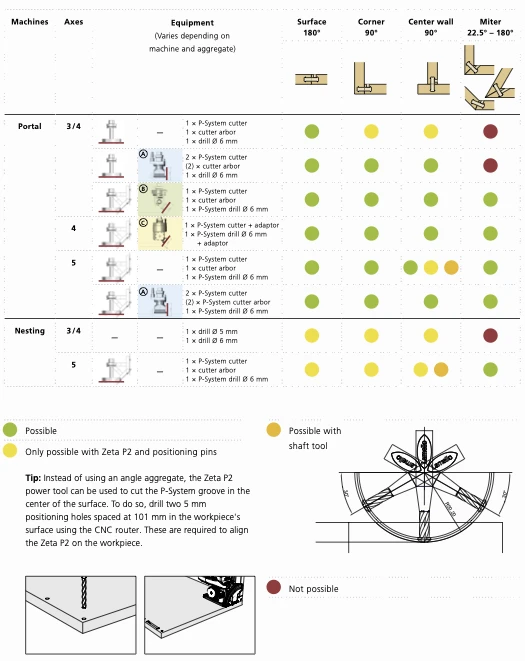

What kind of joints are to be made: surface, corner, center panel, angled?

Refer to the table below for initial details of the requirements

Contact the manufacturer of the machine and procure the macro and CNC software.

Possibly procure an angle aggregate if necessary.

Contact Lamello USA to procure CNC cutters, CNC cutter arbor or CNC drill bit.

Tool Equipment and P-System CNC Tools

May vary depending on machine and aggregate. - Call your CNC Integration experts at Colonial Saw for more information.

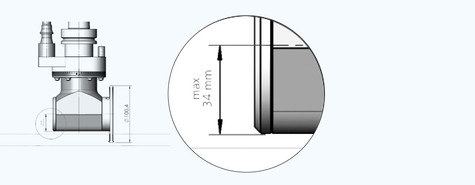

P-System CNC drill bit

- 6 mm, solid carbide, for mitres • L=100 / 35 mm, shaft=10 • 131556

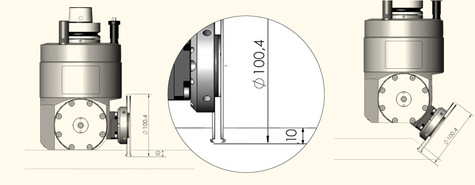

P-System CNC groove cutter, Ø 100.4 x 7

- × 30 mm, 4 / 6.6 / DTK 48 mm, Z3 • 132142

- × 30 mm, 4 / 6.6 / DTK 48 mm, Z6 • 132145

Suitable for all cutter arbors listed below

- × 40 mm, 4 / 5.5 / DTK 52 mm, Z3 • 132143

E.g. for angle aggregates, Flex 5, Flex 5+ - × 16 mm, 4 / 5.5 / DTK 28 mm, Z3 • 132144

E.g. for corner notching aggregate

P-System CNC cutter arbors 30 / DTK 48 mm

- Shaft Ø 20 × 50, L = 102 mm • 132150

- Shaft Ø 25 × 60, L = 102 mm • 1312151

- Shaft Ø 16 × 50, L = 85 mm • 132152

- Shaft Ø 16 × 55, L = 68 mm • 132153

- Shaft Ø 16 × 50, L = 85 mm, with clamping surface (2°- angle) • 132154

E.g. for aggregate for door locks - Shaft Ø 20 × 50, L = 85 mm, with clamping surface (2°- angle) • 132155

E.g. for aggregate for door locks

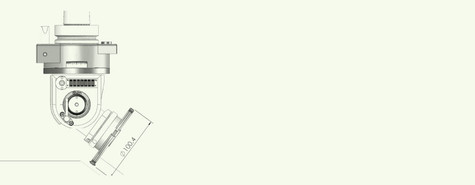

P-System CNC shaft tool cutter Art.No.

- Solid carbide, shaft Ø 12 x 40, L = 80mm • 131342

Only for machining panel centres with 5 axis CNC machines

Positioning pins for Zeta P2

- Ø 5 mm, 1 pairs • 2..5. 1048 Ø 8 mm, 1 pairs • 251066

Positioning clip for Zeta P

- Ø 6 mm • 251067

For positioning in the Clamex access hole (6mm)

Possible

Possible

Only possible with Zeta P2 and positioning pins. Tip: Instead of using an angle aggregate, the Zeta P2 power tool can be used to cut the P-System groove in the centre of the surface. To do so, drill two 5 mm positioning holes spaced at 101 mm in the work piece surface using the CNC machine. These are required to align the Zeta P2 on the work piece.

Only possible with Zeta P2 and positioning pins. Tip: Instead of using an angle aggregate, the Zeta P2 power tool can be used to cut the P-System groove in the centre of the surface. To do so, drill two 5 mm positioning holes spaced at 101 mm in the work piece surface using the CNC machine. These are required to align the Zeta P2 on the work piece.

Possible with shaft tool

Possible with shaft tool

Not possible

Not possible

Aggregates

Angle Aggregate

- One to four spindle angle aggregates

- Corner notching aggregate

- Aggregate for door locks

Manually adjustable swivelling aggregates

Note: Several tool changes required for angle cuts, drilling and P-System grooves

Note: The cutting depth in the center of the surface may be restricted depending on the model

Tip: For miters, save yourself a tool change and drill the hole using a manual drill jig.

Automatically adjustable swivelling aggregates

Note: Automatically adjustable swivelling aggregate with automatic tool changer. The profile groove is restricted to 10 mm in the center of the surface.

(Flex 5+C, from manufacturing year 2015)

Lamello USA - Partners

Call your CNC integration experts at Colonial Saw for further information.

Browse P-System CNC Compatible Products

Filter by Category

Clamex P | Connectors | Connectors & Alignment | Lamello | Medius | P System | P System CNC

Clamex P 14/10 Medius

Clamex P | Connectors | Connectors & Alignment | Flexus | Lamello | P System | P System CNC

Clamex P-14/10 Flexus

Accessories | Cutters, Tools & Accessories | Lamello | Other Products & Accessories | P System | P System CNC

Tenso P-14 Starter Kit

Accessories | Cutters, Tools & Accessories | Lamello | Other Products & Accessories | P System | P System CNC

P System Positioning Pins

Accessories | Cutters, Tools & Accessories | Lamello | Other Products & Accessories | P System | P System CNC