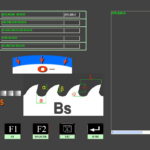

ABM PNK-AC CNC

HSS Cold Saw Grinder

4-Axis CNC HSS Circular saw grinding machine with automatic chamfering and optional chipbreaker.

Product Details

Description

With complete blade processing in one set up (including chamfers) PNK-AC-CNC is the perfect machine for medium to large volume HSS cold saw sharpening shops or large tube and pipe plants that want to sharpen their own blades in house.

- Profiles & chamfers all in one setup

- 4-axis CNC using Beckhoff standard control system

- Windows PC with internet allows remote upgrades and troubleshooting

- Strong 4 hp motor & flood coolant system allows you to manufacture blades from blanks in one pass

- Diverse programming options for tooth removal, tip seat (pocket grinding), steel relief and gullet gumming

Features & Benefits

Specifications

Accessories

Parts, service, and support for your grinding machine.

We’re here to help in whatever way works best for you: on-site, over the phone, or remotely through Zoom, Teams, WhatsApp, or FaceTime.

Colonial Saw's support team is available 8:00 a.m.—8:00 p.m. EST.