Functionality meets convenience

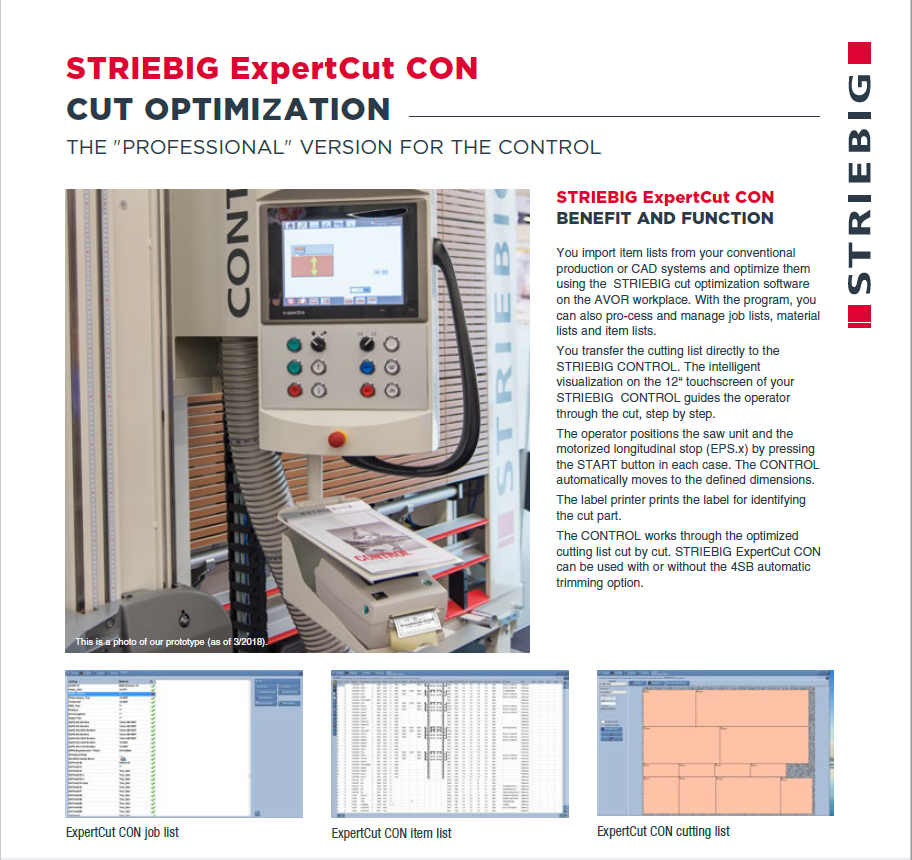

There has never been more operating convenience: the CONTROL can be operated simply by tapping on the screen. The touchscreen‘s 12“ color display visualizes all functions.

With the CONTROL the entire cutting is performed fully automatically. Manual operation is a thing of the past. The automatic saw beam locking feature ensures easy and quick operation.

Premium Class Vertical Cutting Center

Just as the Evolution is the world’s most advanced manual panel saw, the Striebig Control is the world’s most advanced (non-CNC) automatic traveling vertical panel saw. Take all of the features and options of the Evolution; the touch screen, the full wood back support, digital measuring, the automated locking and pivoting of the saw head, locking of the saw beam and rollers, etc., and add automatic travel of the saw in both axes. But it is not just the convenience of the operator not having to move the saw manually! It will cut more parts by being more productive.

Besides variable (and consistent) feed speed, the Control has a panel end sensor, so it stops at the end of the sheet, not at the end of the machine. Similarly, it has memory for where it started the cut and returns to that point, again, not all the way to the other end or top of the machine. It also includes a cycle selector switch so you can have it wait at the end of a cut to give you time to off-load the last piece before the saw returns.

Two more reasons an automatic saw is more productive: on an automatic saw, the operator can be off-loading the last piece while the saw is returning. On a manual saw, that is two separate functions. Also the operator has both hands free to tend to the piece being cut, especially when the top piece of a horizontal cut may be a large, heavy piece.

One of the best and most productive features of the Control is the EPS.Y electronic positioning of the saw head for horizontal cuts. This is in place of the digital measuring on an Evolution. The operator enters the desired dimension of the rip cut (or chooses it from a list), whether from the top or from the bottom of the sheet, confirms, and the saw head goes to that positions and locks itself, ready to make the cut. This is especially great for doing repeat rip cuts from the top of the sheet down, as there is a “repeat” icon for the last dimension cut. The EPS.Y feature can also find the top of the panel and set the saw head for a trim cut that you’ve determined in the parameters!

If you do a lot of rip cutting, such as a closet fabricator or molding manufacturer would, consider a longer 6m saw frame with 17’ cut capacity, where you can have an 8’ sheet, or stack of panels, on the left side, and an 8’ stack on the right, hit the “go” button once and get 2 for 1 with each cycle! The operator can off-load the left pieces while the saw is continuing onto the right side, and can off-load the right side while the saw returns. Touch the “repeat” icon mentioned above, and do it all again, almost completely automatically. What an incredibly productive saw in a fraction of the floor space of a slider or a beam saw!

• Automatic saw travel with variable feed rate 10-25 m/min. (33-82 ft./min.)

• Selectable sawing cycle (cut and return, or cut and stop)

• Panel end sensor and start position memory to save time (instead of having to travel to end of saw)

• EPS.Y programmable saw head positioning for horizontal cuts- great for repeat rip cuts!; includes ABO - automatic, laser light top of panel recognition and positioning for a top trim cut

• Digital measuring X-axis stop (for vertical cuts) with fine adjustment, quick and easy referencing, push-button selection to reference from another cut station, and selectable display increments

• Second measuring channel with three auxiliary stops for repeat cuts, plus “Compact-style” stop

• Extremely stable, all welded steel frame suitable for free-standing or wall-mount installation

• Convenient, sturdy, two-section center shelf with moveable aluminum fingers allows for comfortable working of smaller parts and ability to stage material on one side of the saw

• Automatic recognition and locking of beam at vertical cut stations; unlock at the press of an icon

• Touch-screen control for rotating, plunging, and locking/unlocking of the saw head and beam

• Duplicate buttons conveniently located on front of the saw head for “start cycle”, plunge, and scoring

• Automatic locking of the heavy-duty panel support rollers when cut cycle is started

• Automatic, mechanically shifting, full wood support grid- great for full support of thin, flimsy materials and an added level of dust control

• Laser light to help guide set-up of horizontal cut position

• TRK dust system exceeds European standards; note: requires a collection source

• Vertical cut stations 40 inches on center (1 meter spacing optional for all metric shops)

• USB port to enable uploading of Excel lists of part dimensions

• 7.5 hp, 220V, 3-phase motor with electric brake

• 300 mm (11-7/8”) HFG (hollow-face) carbide saw blade; ideal for melamine and veneers

• Document holder (removable) to keep cut lists in optimum viewing position near control panel

*larger standard frame sizes with cut capacities to 7’4” x 17’4” and special frame sizes with cut capacities up to 10’ x 50’ available upon request

Machine dimensions: 18’ 5”L, 8’ 1”H, 4’ 11” D (free-standing); plus 2’W x 1’D x 4’8”H control box at right end of machine

Weight: 1950 lbs., (approx. 2980 lbs. shipping)

Electrical requirements:3-phase, 220V/20 Amp or 440V/10 Amp service; right side of frame3-phase, 220V, 30A min. circuit

Dust collection: 1000cfm (min), 140mm dia. connection

Compressed Air: 100 psi, 3 cfm (air dryer strongly recommended)

• *EPS.X (Electronic Positioning System) X-axis stop; enter a dimension or pick it from a list on the touch screen and the stop moves to that position- able to reference from any vertical cutting station

• *4SB Bottom Edge Trimming with 660 lb. lifting capacity and full length vacuum holders for trimming bottom edge without turning panel

• WSG Angle Cutting Device with “unipoint” system and fine adjustment to 1/10° for angle cuts to 46°. Wall-mountable wood storage case included.

• *NVV Grooving accessory kit with dial-adjustable depth control for dados and ACM grooving

• *Two-speed saw motor (6hp) for half/full blade speed for hard or brittle materials

• *Extension of the variable feed speed on the low end down to 0.1m/min (4”/min)