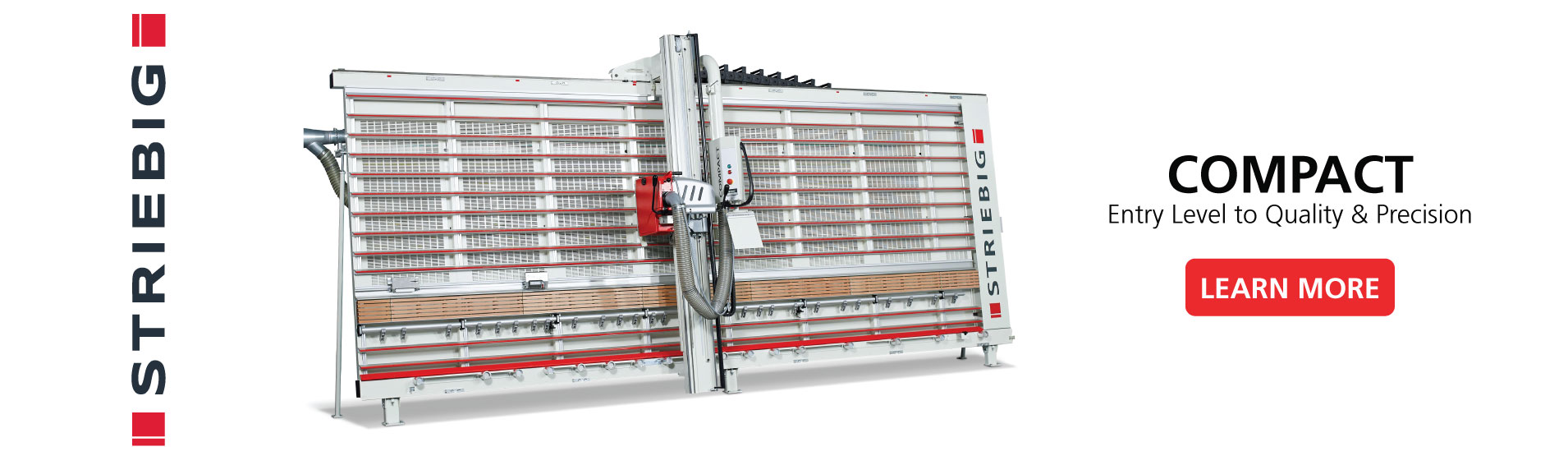

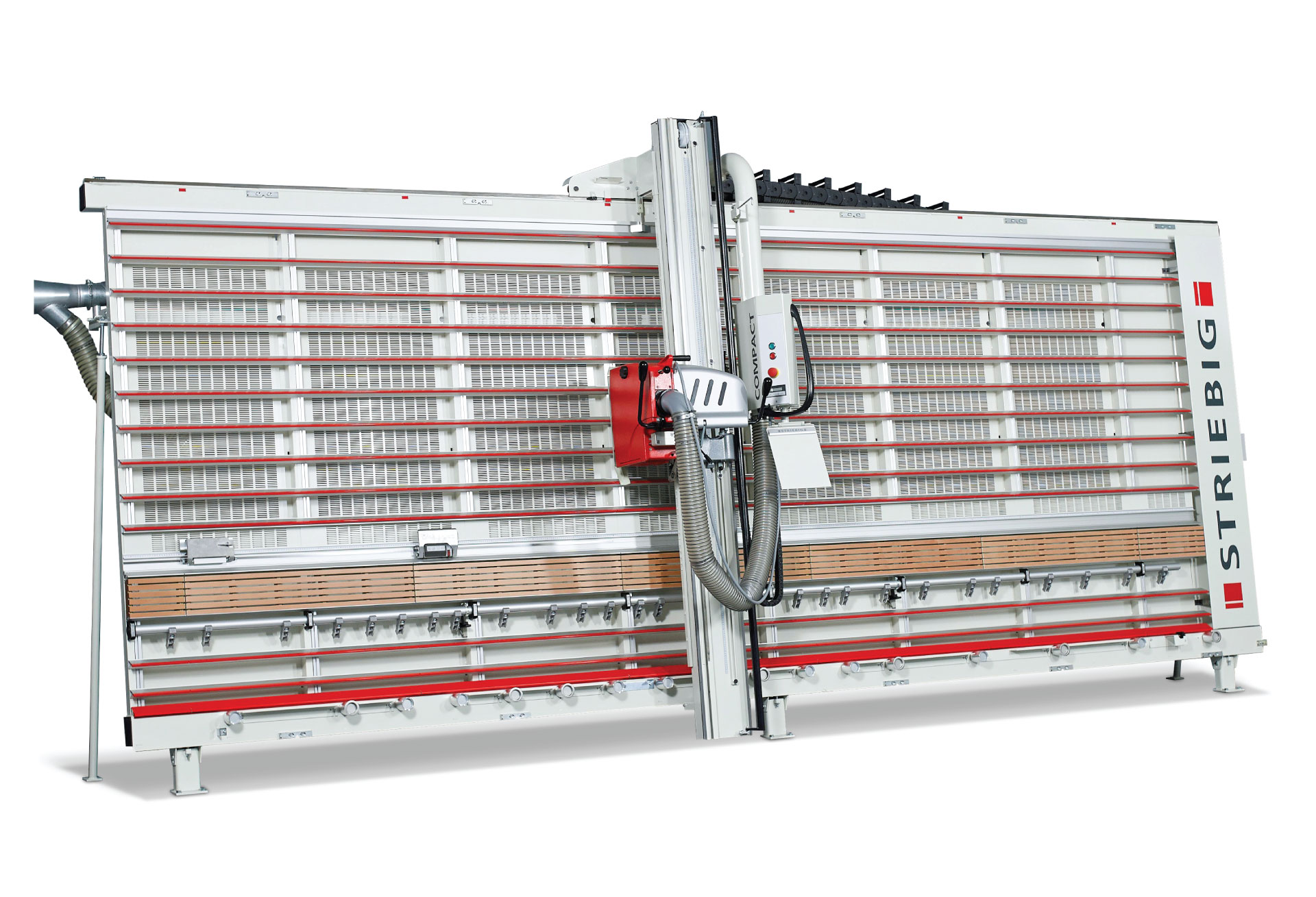

COMPACT

The COMPACT is the entry-level class to the world of precision and quality of STRIEBIG vertical panel saws. Full Specs.

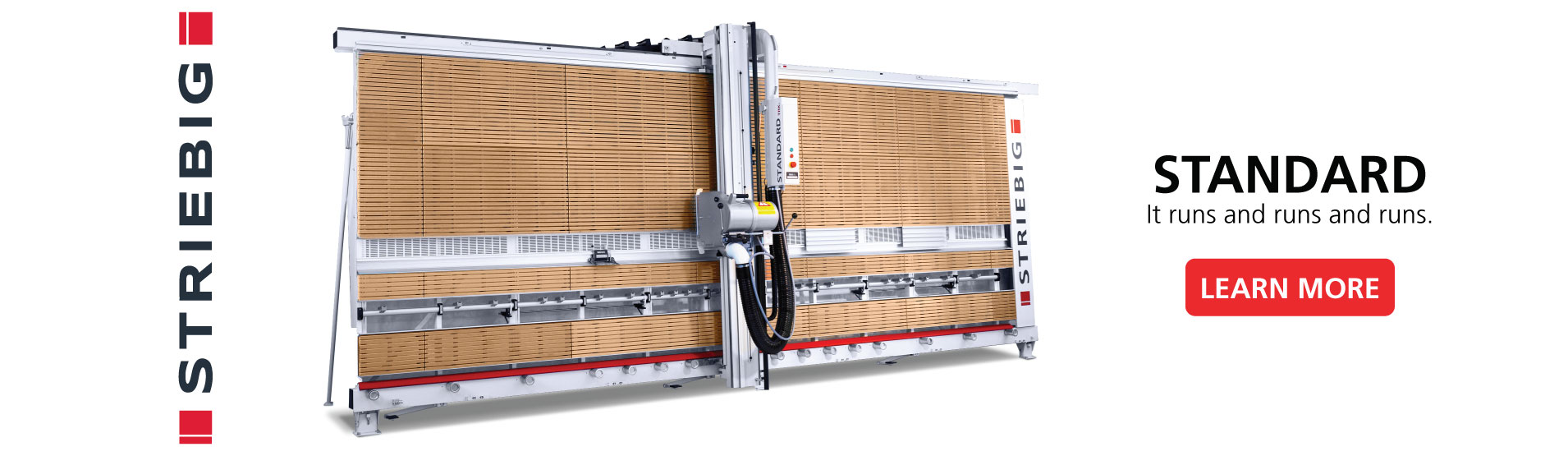

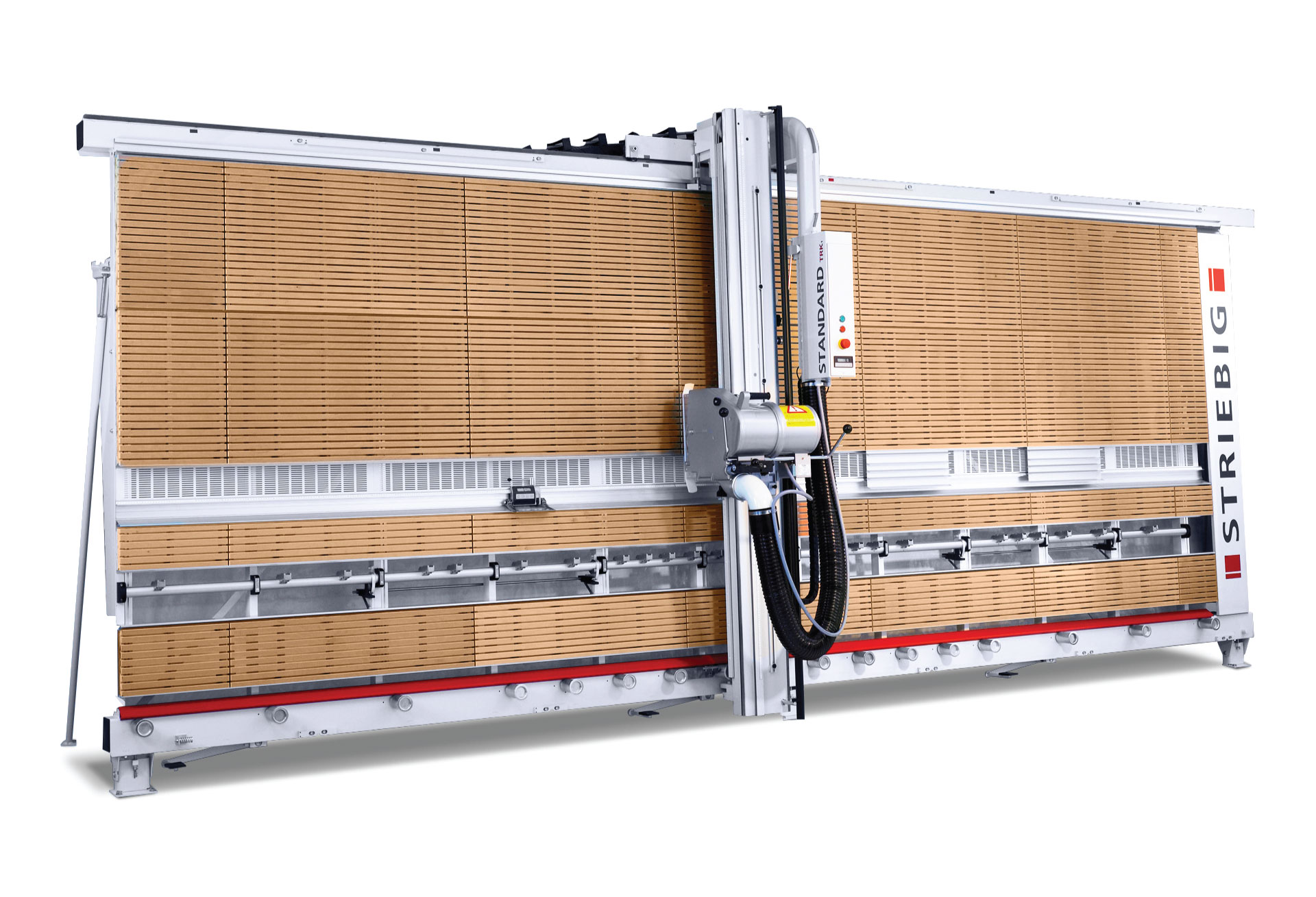

STANDARD

The STANDARD is the world’s best-selling saw of its kind, and has been successful on the market for more than 50 years. It offers proven technology and STRIEBIG's exemplary precision. Full Specs.

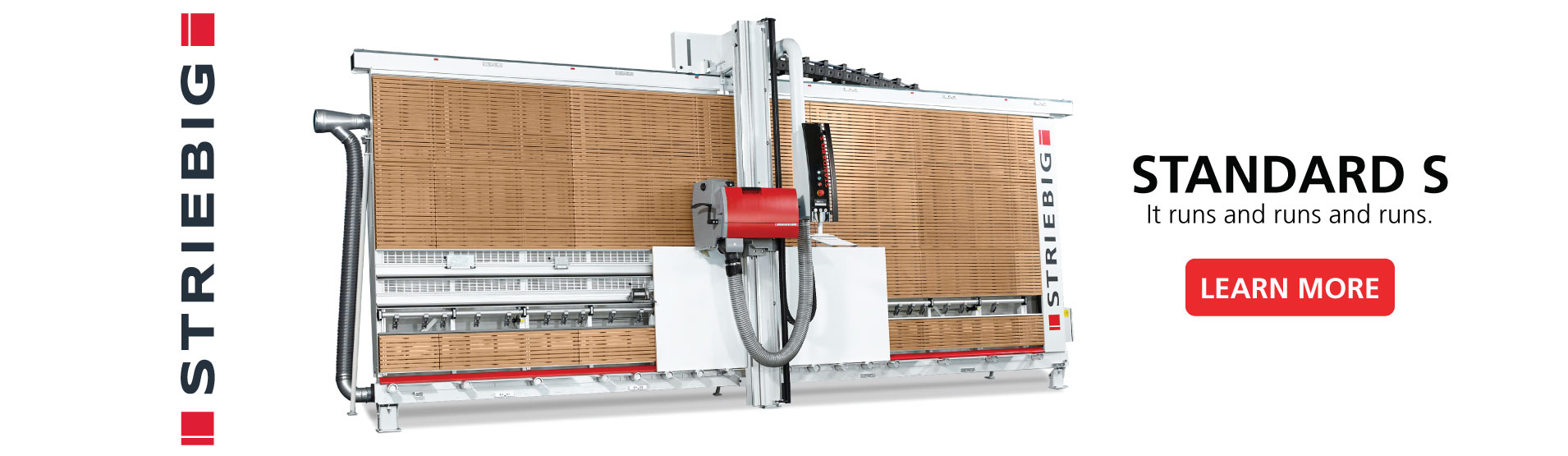

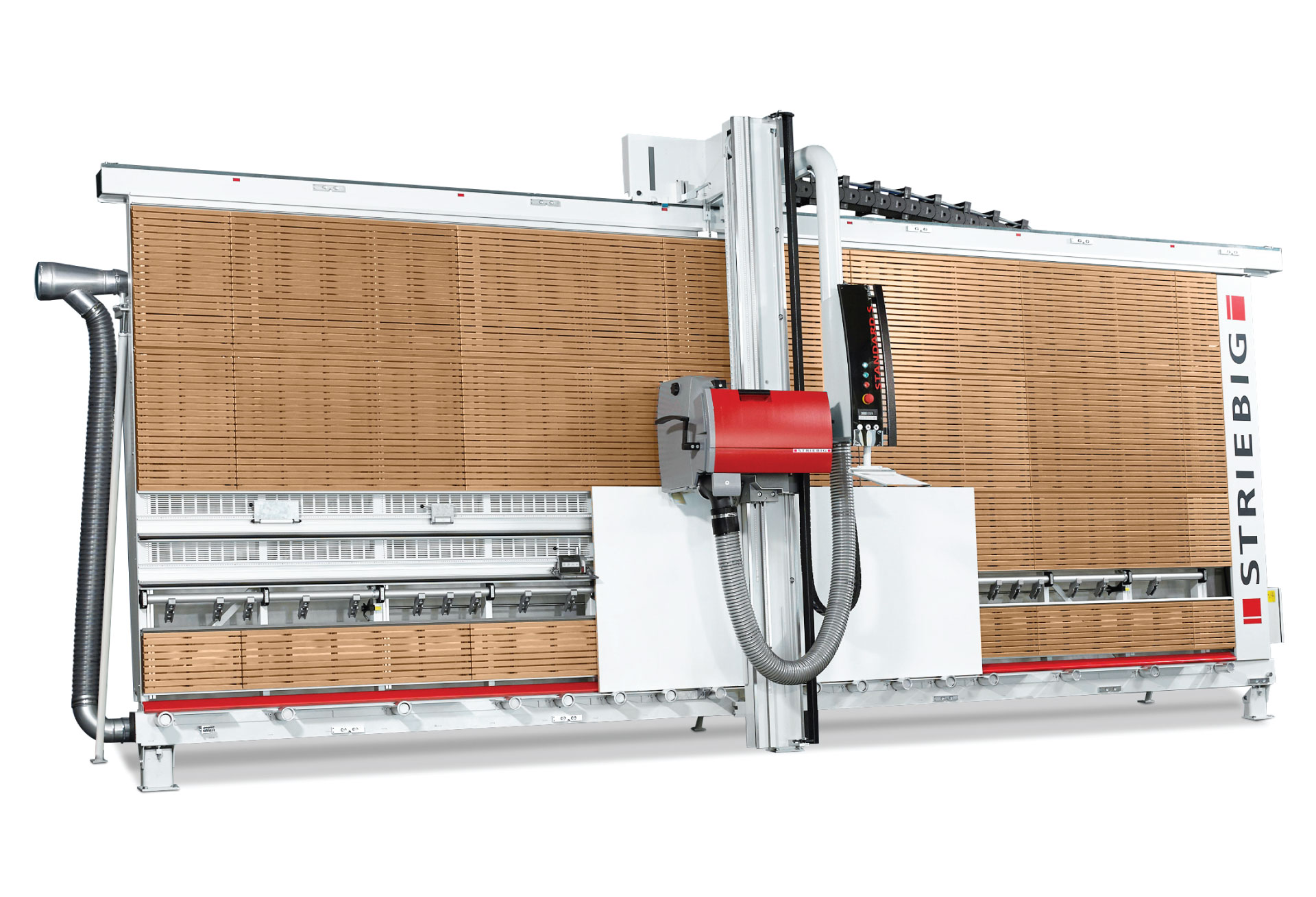

STANDARD S

The new Standard S with optional true split-blade scoring, a contemporary new look and options to make work easier, but the same heart that made the name synonymous with quality. Full Specs.

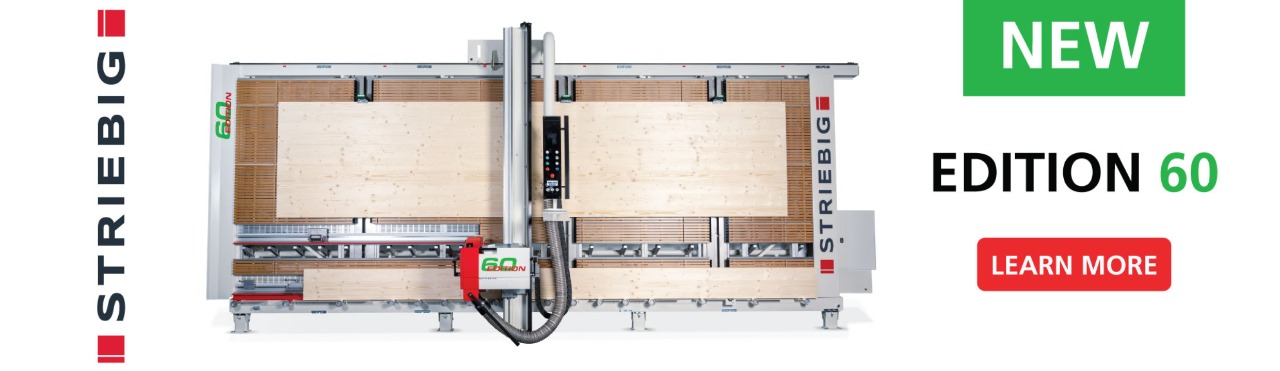

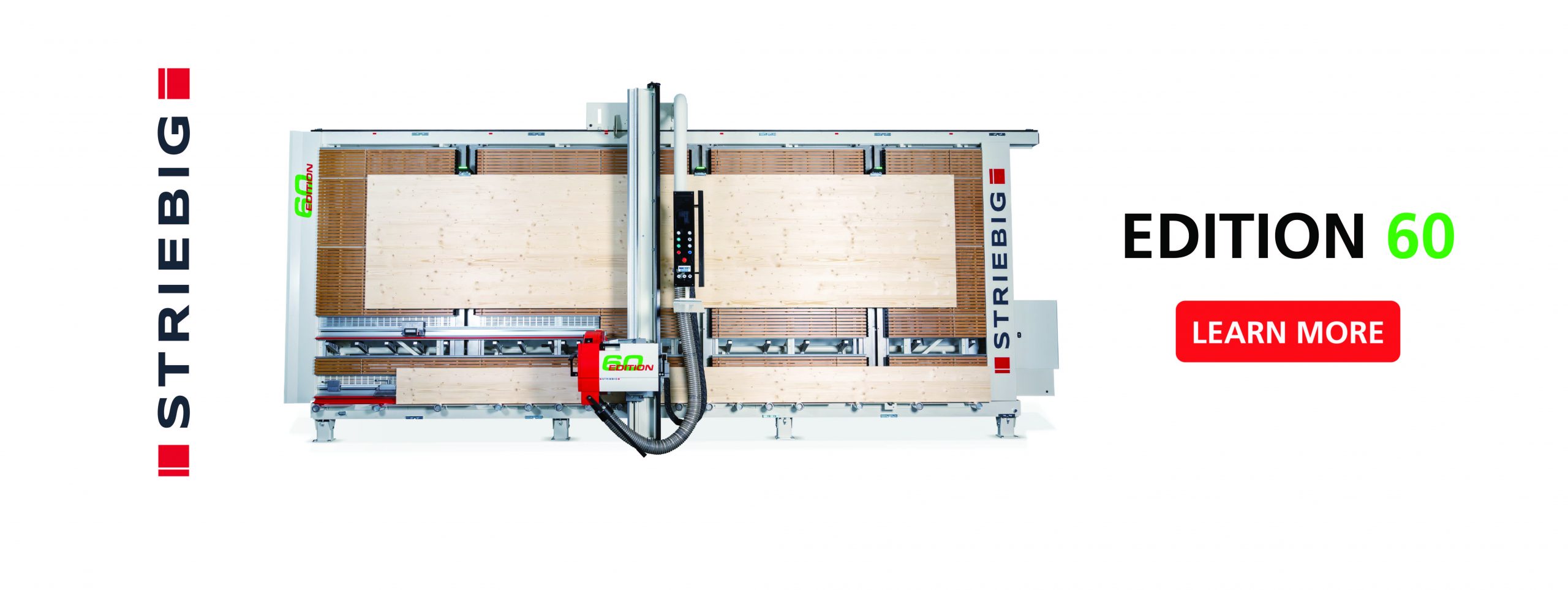

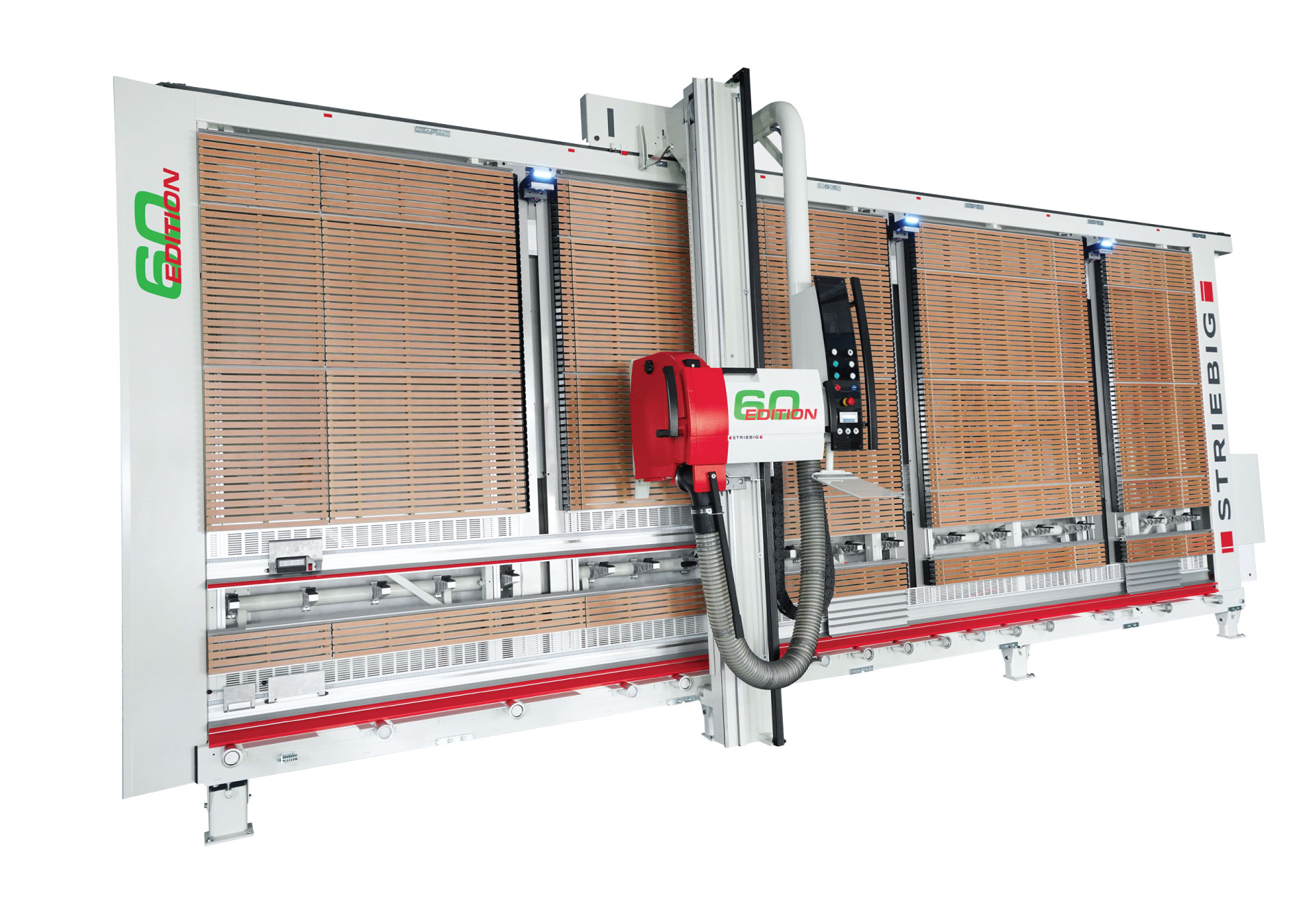

Edition 60

Adding to STRIEBIG's arsenal of features designed to make panel processing safe and easy, the Edition 60 features a strong integrated panel lifting device allowing for ergonomic, smooth cutting of panels by one operator. The comprehensive standard equipment and legendary STRIEBIG accuracy guarantee short processing times and safe operation. Full Specs.

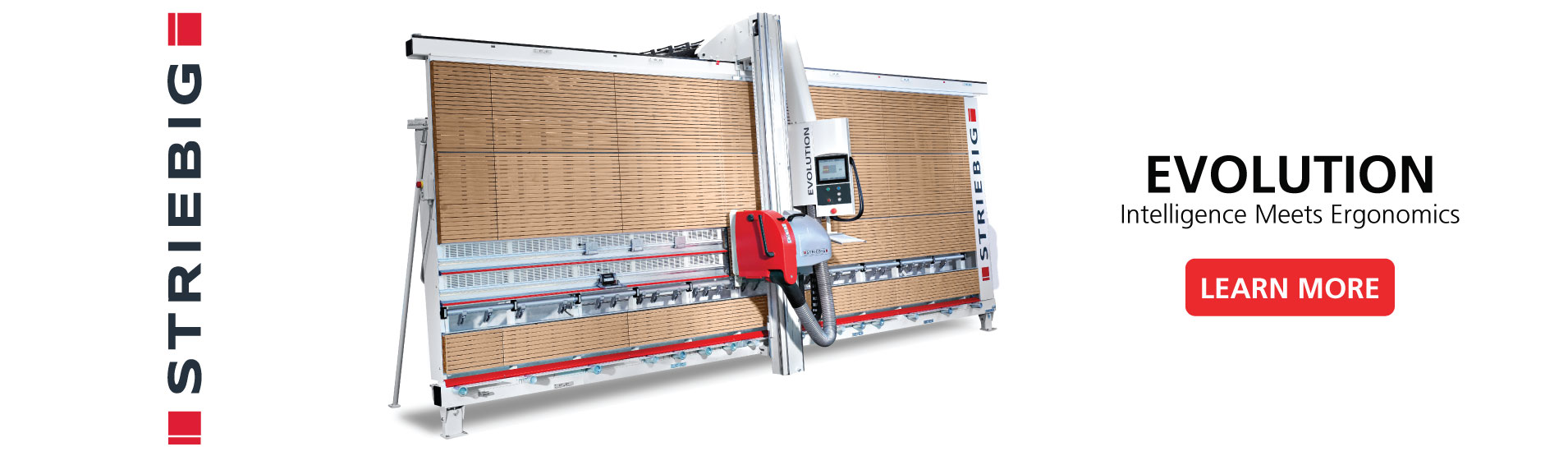

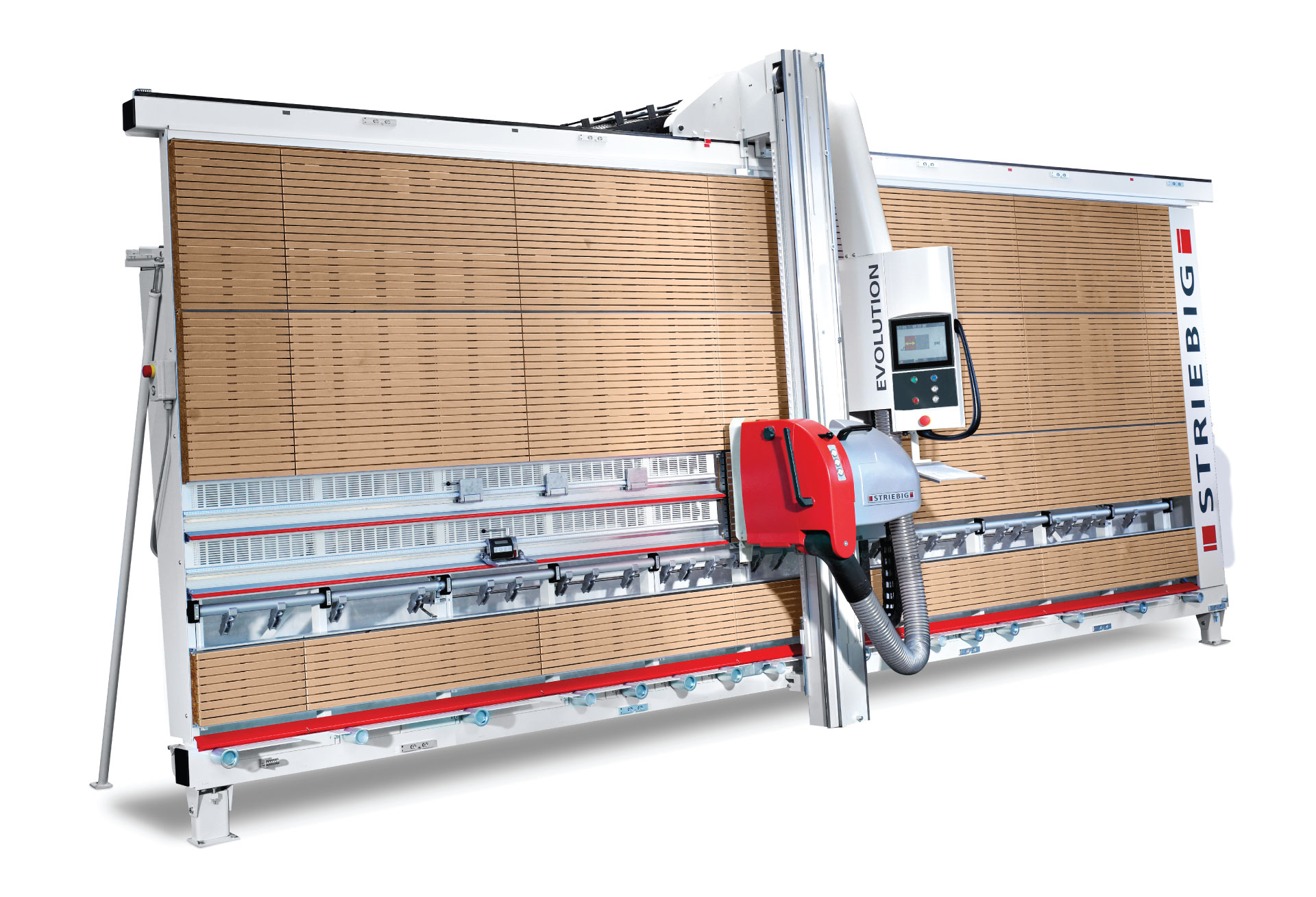

EVOLUTION

For more than a decade the EVOLUTION has maintained its leading position in the manual vertical panel saw sector.

Numerous electronically controlled functions facilitate daily work. Full Specs.

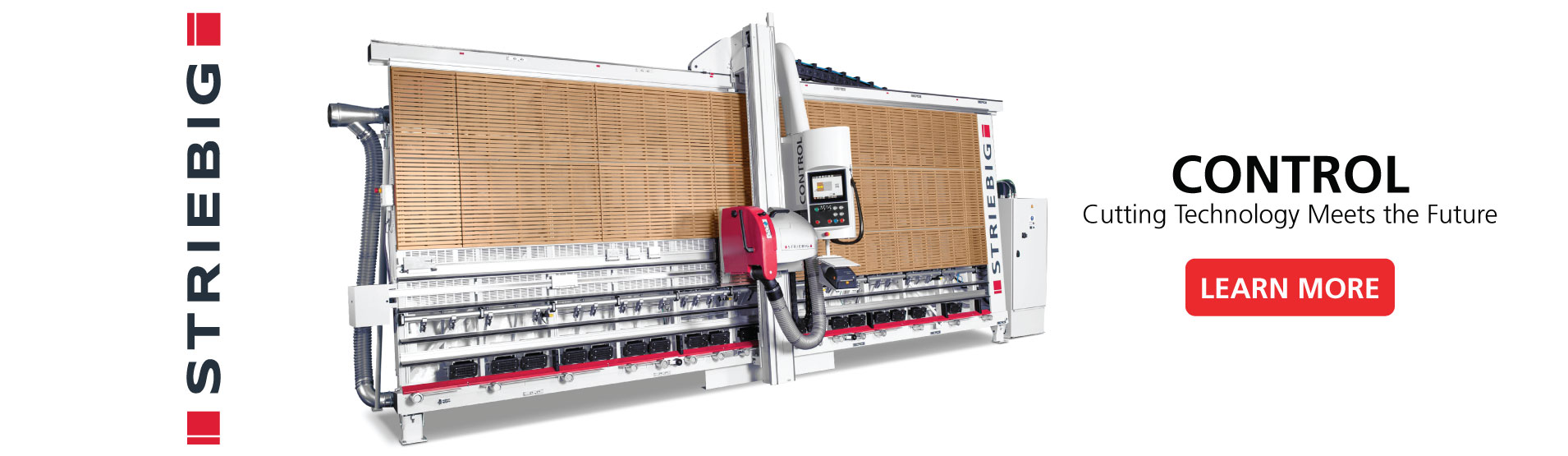

CONTROL

A high degree of sawing procedure automation and a vast array of equipment options are a matter of course.

They allow maximum precision and powerful efficiency. Full Specs.

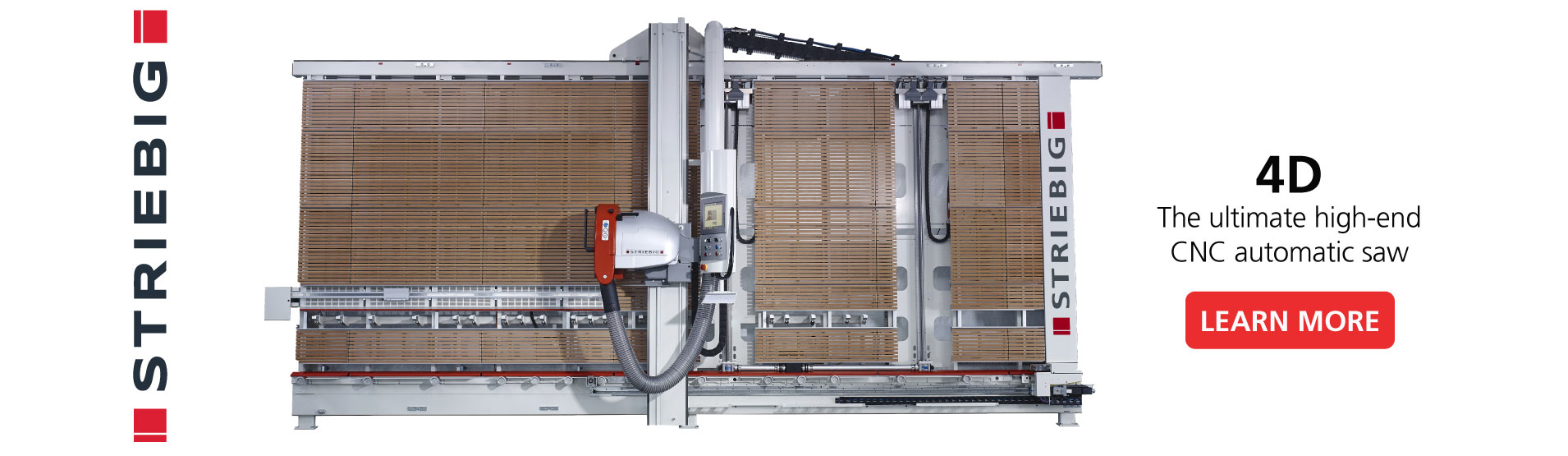

4D

Horizontal and vertical workpiece transport operations are performed fully automatically by the 4D.

The STRIEBIG 4D opens up an all new dimension for vertical cutting technology. Full Specs.

Clear advantages – Vertical system / STRIEBIG system

- Why a vertical

panel saw? - Why choose a

STRIEBIG? - Who needs a

STRIEBIG? - Customers'

Success Stories - Striebig Videos

1. Efficiency:

First and foremost, vertical panel saws were designed to cut big rectangles into smaller rectangles, so of course, they do it more efficiently than an all-around machine like a slider. If you are using a slider solely to cut rectangles to make boxes, you are working harder than you should be!

2. Accuracy, Squareness & Quality of Cut:

It would be difficult to make an argument against an upper-end slider on any of these points, but compared to a table saw, there is no comparison on any of these points. That's mainly because on a vertical saw, the panel is stationary and the saw moves on precision guide-ways through the material, and you're not relying on an operator to keep the work-piece up against a fence. The quality of cut issue is extremely apparent when cutting solid surface material and melamine.

3. Material Handling and Operator Ease:

This is especially true of a Striebig because of the panel rollers but is true of all verticals. Just think about the way you would carry a sheet from one end of the shop to the other - it's easier to handle it vertically. Now think about wrestling a sheet horizontally up to and through a table saw.

4. Space Savings:

Vertical panel saws use very little floor space. 70 sq. ft. is all that's required to cut up to 5' x 10' panels (or 95 sq. ft. for 6' x 14'), as opposed to 200 sq. ft. min. for a table saw or slider just to cut 4' x 8' sheets! Remember you need 8' in front of the blade, 8' behind the blade, 8' to the left, and 4' to the right. How much is your leased floor space worth each month?

5. Safety:

A continually covered saw blade is traveling through a stationary panel. There are no fingers moving past a blade sticking up through a table!

First and foremost, vertical panel saws were designed to cut big rectangles into smaller rectangles, so of course, they do it more efficiently than an all-around machine like a slider. If you are using a slider solely to cut rectangles to make boxes, you are working harder than you should be!

2. Accuracy, Squareness & Quality of Cut:

It would be difficult to make an argument against an upper-end slider on any of these points, but compared to a table saw, there is no comparison on any of these points. That's mainly because on a vertical saw, the panel is stationary and the saw moves on precision guide-ways through the material, and you're not relying on an operator to keep the work-piece up against a fence. The quality of cut issue is extremely apparent when cutting solid surface material and melamine.

3. Material Handling and Operator Ease:

This is especially true of a Striebig because of the panel rollers but is true of all verticals. Just think about the way you would carry a sheet from one end of the shop to the other - it's easier to handle it vertically. Now think about wrestling a sheet horizontally up to and through a table saw.

4. Space Savings:

Vertical panel saws use very little floor space. 70 sq. ft. is all that's required to cut up to 5' x 10' panels (or 95 sq. ft. for 6' x 14'), as opposed to 200 sq. ft. min. for a table saw or slider just to cut 4' x 8' sheets! Remember you need 8' in front of the blade, 8' behind the blade, 8' to the left, and 4' to the right. How much is your leased floor space worth each month?

5. Safety:

A continually covered saw blade is traveling through a stationary panel. There are no fingers moving past a blade sticking up through a table!

World's First Vertical Panel Saw with Pivoting Head

In 1958, Ludwig Striebig, a Swiss cabinetmaker, was tired of ripping his panels by pushing the panel thru the power saw on his vertical saw. Realizing it would be much easier if the panel were stationary and the sawblade moved, he designed and built a complete wooden prototype to test his idea. Fellow cabinetmakers asked Ludwig to please make this new concept saw, and in 1961 the Striebig Company began producing the world's first vertical panel saws with a specially designed, pivoting saw head attached to a rolling beam. For the first time in the world, all cuts could be made with the panel stationery. From 1961 until today, the Striebig Company has kept Ludwig Striebig's tight focus - to manufacture only vertical panel saws and to make them the best in the world.

1. Quality:

Striebig has long been known as the standard of quality in vertical panel saws. They are Swiss engineered and built by a company whose only business has been vertical panel saws for over 50 years.

2. Accuracy, Squareness & Quality of Cut:

Each Striebig machine is set-up and tested at the factory in Luzern, Switzerland to ensure its accuracy to .004" and to guarantee perfectly square, chip free cuts that are either ready to glue up or go to the edgebander.

3. Material Handling and Operator Ease:

The heavy-duty panel rollers are the key here. They permit loading and positioning of even the heaviest of panels with minimal effort. There is no need to raise and lower the rollers just to move the panel a little to the left or right. They also enable one person to "flip" a sheet by himself if he needs to have a trimmed edge on the bottom reference surface. There is also the smooth plunge and counterbalance of the saw head, and overall smooth travel of the saw in the cutting operation. They are difficult to quantify, but easy to feel, like the feel of a great sports car!

4. Durability:

Obsolescence is not built in. Just ask someone who has been using his Striebig (and cutting square) for the last 20 years. They just keep running and running, some of them in the harshest environments!

5. Versatility:

No other vertical saw manufacturer has the range of frame sizes and variety of features and options available. True split-blade scoring, angle cutting, digital measuring, programmable positioning, dado cutting, V-grooving, and lifting system that allows trimming of the bottom edge without flipping the panel. We've got it!

6. Simplicity:

Controls and operation are simple and logical. They are engineered so that it is difficult for an operator to use it improperly or unsafely, or to damage it. The learning curve is almost nonexistent. It takes about an hour to train most people to use the machine.

Click here to read more about the benefits of owning a STRIEBIG including interviews with current STRIEBIG owners.

In 1958, Ludwig Striebig, a Swiss cabinetmaker, was tired of ripping his panels by pushing the panel thru the power saw on his vertical saw. Realizing it would be much easier if the panel were stationary and the sawblade moved, he designed and built a complete wooden prototype to test his idea. Fellow cabinetmakers asked Ludwig to please make this new concept saw, and in 1961 the Striebig Company began producing the world's first vertical panel saws with a specially designed, pivoting saw head attached to a rolling beam. For the first time in the world, all cuts could be made with the panel stationery. From 1961 until today, the Striebig Company has kept Ludwig Striebig's tight focus - to manufacture only vertical panel saws and to make them the best in the world.

1. Quality:

Striebig has long been known as the standard of quality in vertical panel saws. They are Swiss engineered and built by a company whose only business has been vertical panel saws for over 50 years.

2. Accuracy, Squareness & Quality of Cut:

Each Striebig machine is set-up and tested at the factory in Luzern, Switzerland to ensure its accuracy to .004" and to guarantee perfectly square, chip free cuts that are either ready to glue up or go to the edgebander.

3. Material Handling and Operator Ease:

The heavy-duty panel rollers are the key here. They permit loading and positioning of even the heaviest of panels with minimal effort. There is no need to raise and lower the rollers just to move the panel a little to the left or right. They also enable one person to "flip" a sheet by himself if he needs to have a trimmed edge on the bottom reference surface. There is also the smooth plunge and counterbalance of the saw head, and overall smooth travel of the saw in the cutting operation. They are difficult to quantify, but easy to feel, like the feel of a great sports car!

4. Durability:

Obsolescence is not built in. Just ask someone who has been using his Striebig (and cutting square) for the last 20 years. They just keep running and running, some of them in the harshest environments!

5. Versatility:

No other vertical saw manufacturer has the range of frame sizes and variety of features and options available. True split-blade scoring, angle cutting, digital measuring, programmable positioning, dado cutting, V-grooving, and lifting system that allows trimming of the bottom edge without flipping the panel. We've got it!

6. Simplicity:

Controls and operation are simple and logical. They are engineered so that it is difficult for an operator to use it improperly or unsafely, or to damage it. The learning curve is almost nonexistent. It takes about an hour to train most people to use the machine.

Click here to read more about the benefits of owning a STRIEBIG including interviews with current STRIEBIG owners.

Small Shops

• Faster and safer than a table saw or slider.

Space & Safety Conscious Shops

• Legendary for precision, safety and space savings.

Shops Cutting Oversized Panels

• Small investment and easy handling of panels up to 10 x 30 ft.

Medium & High Volume Shops

• Offline saw for rework, short custom runs, or to free up a CNC for more complicated parts!

Vertical Panel Saw Streamlines Fabrication of Aluminum Composite Material

"People don't realize what it is, but they see it everywhere," says Doug Clay. Clay is talking about aluminum composite material (ACM) - a layer of low-density polyethylene permanently sandwiched between two aluminum skins. The sleek, high-tech look that ACM panels bring to a storefront, a curtainwall, or even a whole building has been popular in Europe for decades and seems to be catching on in the U.S. While American architects tend to shy away from the Lego-like colors of some European ACM-clad structures, they specify the material enough to keep Clay busy. As general manager of the fabrication division of Karas & Karas Glass Co., Inc., he oversees bidding and fabrication for a multitude of construction projects in and around Boston. He works with glass and aluminum plate too, but reports that a steady increase in ACM jobs has made his shop a major profit center for his employer. He saw it coming. Under Clay's stewardship, Karas & Karas has become a recognized leader in ACM construction throughout New England. Among the factors contributing to the contractor's reputation for quality and efficiency is Clay's purchase of two Swissmade Striebig vertical panel saws in the late 1990s.

"People don't realize what it is, but they see it everywhere," says Doug Clay. Clay is talking about aluminum composite material (ACM) - a layer of low-density polyethylene permanently sandwiched between two aluminum skins. The sleek, high-tech look that ACM panels bring to a storefront, a curtainwall, or even a whole building has been popular in Europe for decades and seems to be catching on in the U.S. While American architects tend to shy away from the Lego-like colors of some European ACM-clad structures, they specify the material enough to keep Clay busy. As general manager of the fabrication division of Karas & Karas Glass Co., Inc., he oversees bidding and fabrication for a multitude of construction projects in and around Boston. He works with glass and aluminum plate too, but reports that a steady increase in ACM jobs has made his shop a major profit center for his employer. He saw it coming. Under Clay's stewardship, Karas & Karas has become a recognized leader in ACM construction throughout New England. Among the factors contributing to the contractor's reputation for quality and efficiency is Clay's purchase of two Swissmade Striebig vertical panel saws in the late 1990s.Read the full story here:

Karas and Karas (258.7kb pdf)

The Ferrari of Vertical Panel Saws?

Cabinetmaker Norm Franzle says he can't call his Striebig Optisaw 2 the Ferrari of panel saws because it was not too expensive and never breaks down. "When it comes to performance, Striebig is the best," says the California cabinetmaker. He and his employees at Franzle Custom Home Specialties in Sun Valley, California, rely on the 7.5HP vertical Optisaw for unfailing accuracy in the cutting of panels for their "frameless" European-style cabinets with hidden hinges and clean, elegant lines. It would be difficult to find a more satisfied Striebig customer. "How many times in your life have you made a major purchase and been completely happy five years later?" Franzle asks. "It doesn' t happen very often, but that is just the situation here."

Cabinetmaker Norm Franzle says he can't call his Striebig Optisaw 2 the Ferrari of panel saws because it was not too expensive and never breaks down. "When it comes to performance, Striebig is the best," says the California cabinetmaker. He and his employees at Franzle Custom Home Specialties in Sun Valley, California, rely on the 7.5HP vertical Optisaw for unfailing accuracy in the cutting of panels for their "frameless" European-style cabinets with hidden hinges and clean, elegant lines. It would be difficult to find a more satisfied Striebig customer. "How many times in your life have you made a major purchase and been completely happy five years later?" Franzle asks. "It doesn' t happen very often, but that is just the situation here."It was a different story six years ago, when Franzle was still using a quirky sliding table saw he calls "a piece of junk." "There was one problem after another, which meant downtime and lots of service calls, and I ended up completely dissatisfied," Franzle recalls. "I even tried to return it, but the manufacturer wouldn't take it back." In the market for something different, he started looking at vertical panel saws. Friends at a blade-sharpening shop told him the best of them all - the "Ferrari," they called it - is made in Switzerland by Striebig.

Read the full story here:

The Ferrari of Vertical Panel Saws? (87.4kb pdf)

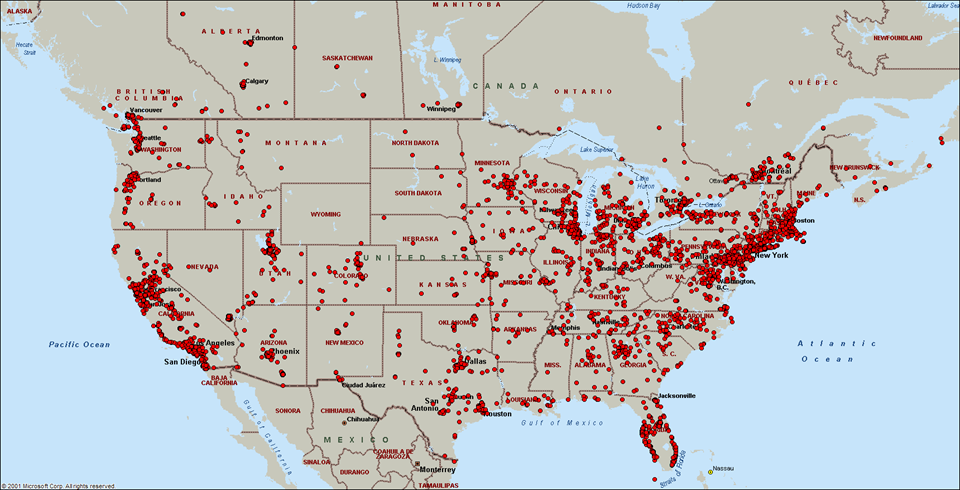

Authorized STRIEBIG

US & Canadian Dealers

Colonial Saw has authorized STRIEBIG dealers throughout the United States and Canada.

For all other areas in North America, please contact our STRIEBIG Product Manager Dave Bull in our main office in Massachusetts at (888) 777-2729 extension 204 or E-mail info@csaw.com.

For all other areas in North America, please contact our STRIEBIG Product Manager Dave Bull in our main office in Massachusetts at (888) 777-2729 extension 204 or E-mail info@csaw.com.