News

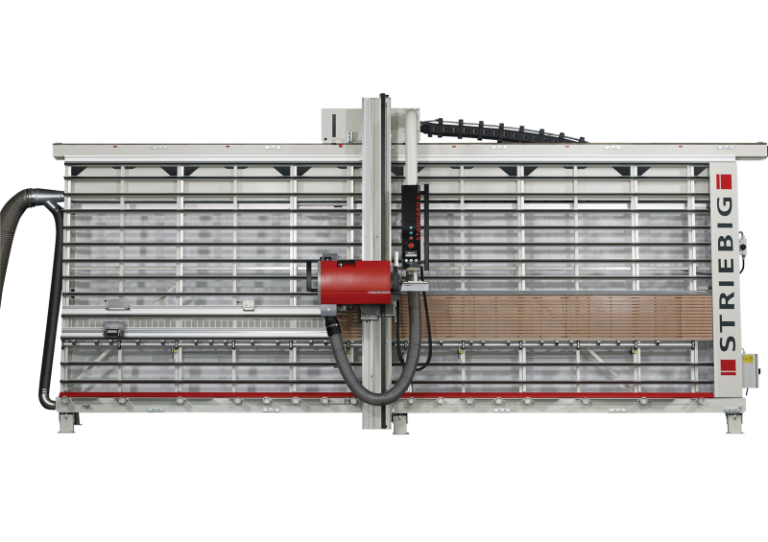

STRIEBIG helps high-volume lumber & hardware store provide superior customer service

TH&H Hardwoods and Hardware is a high volume, full-warehouse resource primarily serving contractors and builders, as well as the general public. With 250 woodworkers coming through their San Diego, CA location per day, their STRIEBIG vertical panel saw is a key piece of how they’ve delivered superior service to their customers buying sheet goods since 2016.

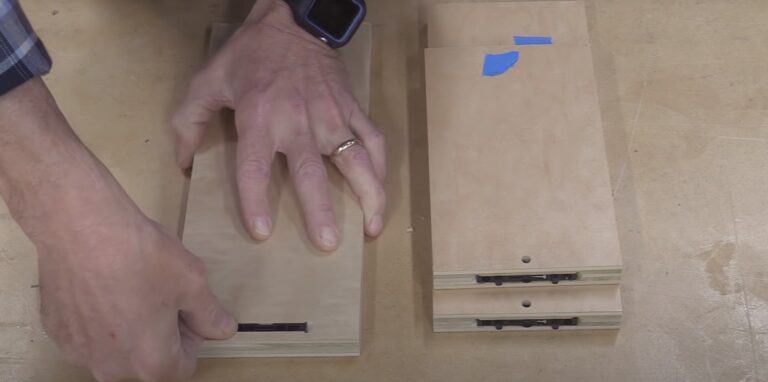

Guy’s Woodshop talks P-System Connectors

“I get a ton of questions about the Lamello Zeta P2 joiner and the P System connectors that I used in my Media Console build https://youtu.be/EFp10zMzsGw and my Kitchen Cabinet build https://youtu.be/g4TaI0mH1C8 videos. Hopefully this will fully answer any questions you may have. If it doesn’t, please ask! Help support my channel and what I…

V-Grooving & Coving on STRIEBIG

Colonial Saw is pleased to announce the expanded capability for V-grooving and coving solid surface material on three more STRIEBIG models: the Standard S, Evolution, and Control. STRIEBIG originated V-grooving and coving solid surface on a vertical panel saw in the late ‘90s beginning with their “Optisaw 2” model, and now all of the 7-1/2hp…

Lamello – A Profile in Precision

Woodworkers have an innate professional curiosity, always looking for a better method, a better end result. Hermann Steiner was no different as he wrestled with the process of joining chip board panels, an interesting new material for cabinetmakers in the early fifties. Bedridden with a winter fever, he concentrated on the problem until a solution came to him as he stared at his shutters: cut small opposing grooves into the panels that wouldn’t weaken the chip board and connect them using small wooden biscuits. Simple, yet game-changing.

Cabineo Case Study: Select Millwork

A SURVIVAL AND SUCCESS STORY The Great Recession presented challenges to mostwoodworking businesses in one form or another, and SelectMillwork in Irving, Texas was no different. After foundingtheir company in 2004, business partners Paul Gause andBilly Harrington were faced with some difficult decisionswhen the project pipeline started to dry up for them in2010, including being…

Tenso Case Study: Northland Woodworks

Lamello’s 2017 contest for real-world Zeta P2 uses spurred a robust response and many pleasant surprises. “There are many standard applications the product was designed for, but the system is so innovative when creative people get ahold of it they come up with applications that the manufacturer hadn’t thought of,” said Chris Hofmann, Lamello’s eastern U.S. product manager.

Clamex Case Study: Camp Good Days

Lamello’s 2017 contest for real-world Zeta P2 uses spurred a robust response and many pleasant surprises. “There are many standard applications the product was designed for, but the system is so innovative when creative people get ahold of it they come up with applications that the manufacturer hadn’t thought of,” said Chris Hofmann, Lamello’s eastern U.S. product manager.

Lamello Zeta P2: Klevr Case Study

Lamello’s 2017 contest for real-world Zeta P2 uses spurred a robust response and many pleasant surprises. “There are many standard applications the product was designed for, but the system is so innovative when creative people get ahold of it they come up with applications that the manufacturer hadn’t thought of,” said Chris Hofmann, Lamello’s eastern U.S. product manager.

Lamello 2018 Travelogue

Last spring Lamello and Colonial Saw issued the Lamello Dealer Challenge, an unprecedented contest to grow Lamello and the Zeta P2 markets in the United States and reward top-selling dealers. The prize: an all-expense paid trip to Switzerland to tour the Lamello factory, participate in hands-on demonstrations and enjoy Switzerland’s natural beauty.

Lamello History

Woodworkers have an innate professional curiosity, always looking for a better method, a better end result. Hermann Steiner was no different as he wrestled with the process of joining chip board panels, an interesting new material for cabinetmakers in the early fifties. Bedridden with a winter fever, he concentrated on the problem until a solution came to him as he stared at his shutters: cut small opposing grooves into the panels that wouldn’t weaken the chip board and connect them using small wooden biscuits. Simple, yet game-changing.

Colonial Saw to Debut New Striebig Model

Colonial Saw, Inc., U.S. distributor of market-leading Striebig vertical panel saws, recently announced a new model coming to the U.S. market in 2018. The new Striebig Standard S model adds another level to their universal vertical sawing technology with integrated new elements and retained proven benefits. Chief among them, the Standard S will incorporate scoring as a standard feature and sport a sleek new operator control panel.

Industry machines in place for MiLL training center

You could say the pieces are in place at the MiLL National Training Center.

The shop floor is filled with equipment and signs to recognize the many industry partners. Machines include a Weeke CNC router, Stiles edgebander, Timesavers sander, Altendorf table saw, SCM case clamp, Striebig panel saw, JLT clamping systems, eight TigerStops, many Kreg products, Bessey clamps and Rikon machinery.

1000th Lamello Zeta P2 Cuts a Swath in the Industry

Lamello USA, a division of Colonial Saw, recently celebrated the sale of the one thousandth Lamello Zeta P2, a precision tool to cut the full range of slots for the P System connector series. The 1000th U.S. purchase of the revolutionary tool was made by Weber’s Cabinet and Fixture Company in Reno, Nevada