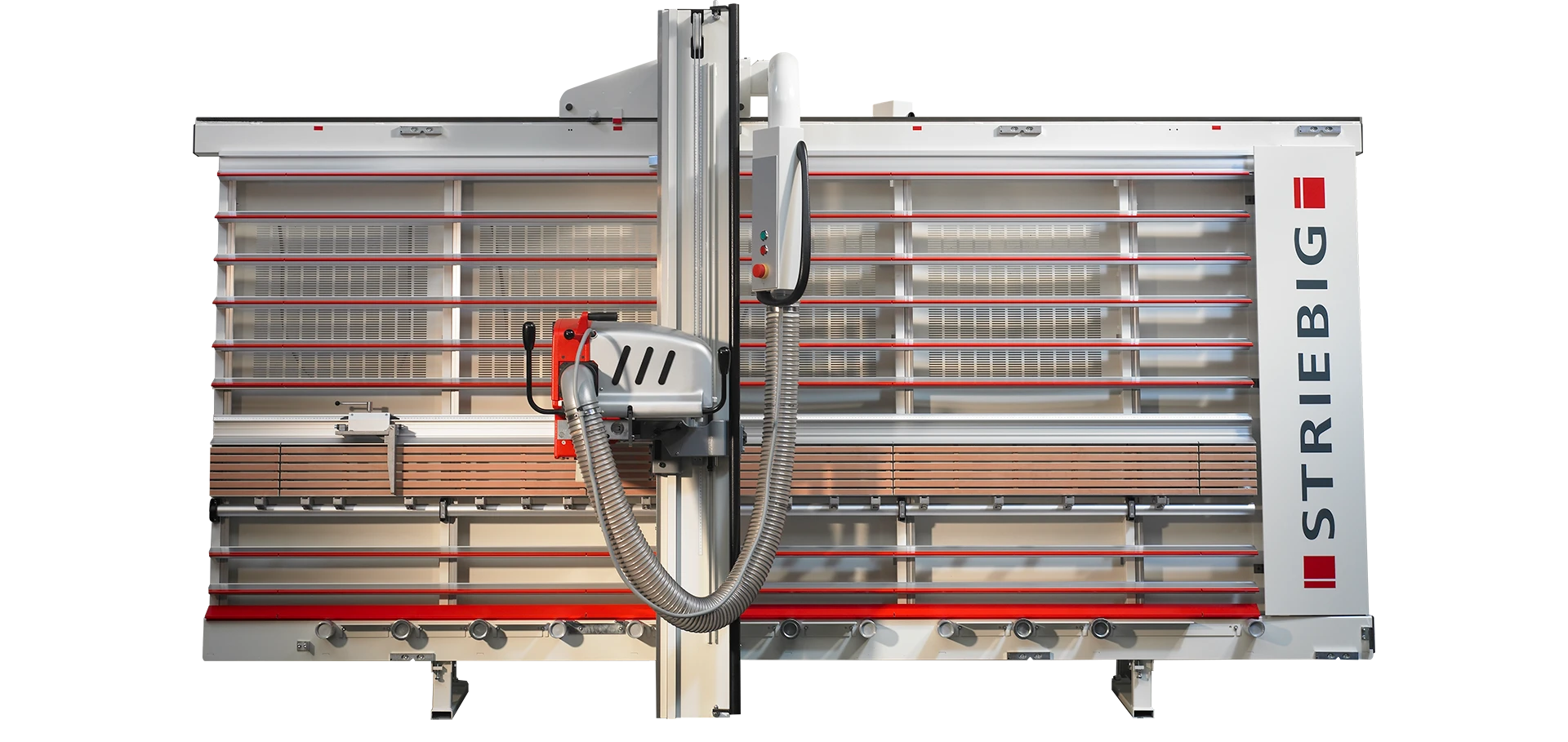

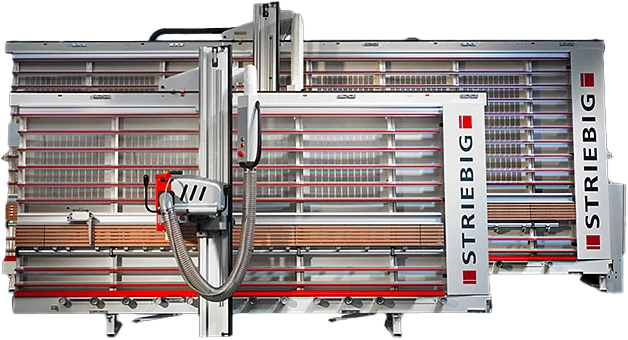

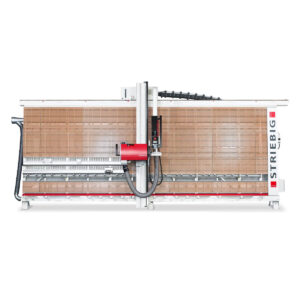

Yes! Since Ludwig Striebig invented his machine in the late ‘50s, Striebig has always been focused on the finish cut and cut quality. Some materials, including melamines, developed in the last 30 years have more sensitive coatings and therefore require scoring on one side in order to have a good clean cut on both sides of the sheet. There are two methods of scoring employed on most Striebig models. Over 20 years ago, Striebig developed its first true scoring saw unit, and has continued to develop and improve this concept to this day. They are belt-driven units that use split-blade type scoring saw blades. The two blades are adjusted for width either with shims in its simplest version, or by the simple turn of the T-handle Allen wrench in the advanced adjustable (“Quick-set”) version. This blade is even available in diamond for extra-long life. These scoring saw units are available on all Striebig models except the Standard TRK. Striebig has never entertained the idea of scoring panels with an inexpensive, “scratch-knife” type of scoring that others employ. These systems simple do not work very well on a wide variety of materials, and you never see them used on other types of saws, like sliding table saws or beam saws, so…

The other method of scoring widely used on Striebig saws without the optional scoring saw, is the back-scoring or climb-cut scoring method, where the main blade is used to score the panel. On a vertical panel saw, the side of the panel that is up against the backing grid is the side that will get the reliably good finish cut (like the top side when you’re using a table saw). It’s the side you’re looking at that is the side that needs scoring. When you use the back-scoring method for a vertical cut, you start with the saw head at the bottom. You plunge in until the saw blade just touches the panel (the riving knife can serve very nicely as a depth stop in this position- the blade is just a bit deeper than the riving knife), and you bring the saw head up to the top of the panel. You see the score mark right in front of you. At the top of the panel you plunge the saw to full depth and make your normal separating cut to the bottom. But then just leave the saw at the bottom, so you can start your next cut. You’ve completed one cut cycle. You’ve just started and ended the cycle in a different place. It’s the same amount of work! And the same blade that did the scoring did the cutting, so there are no alignment issues- simple! The same concept applies to horizontal cuts. When you have to score enough panels, or are using an automatic saw, a scoring saw unit will pay for itself in reduced saw sharpening bills.