Control

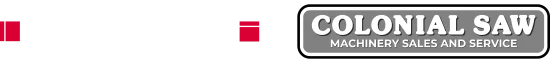

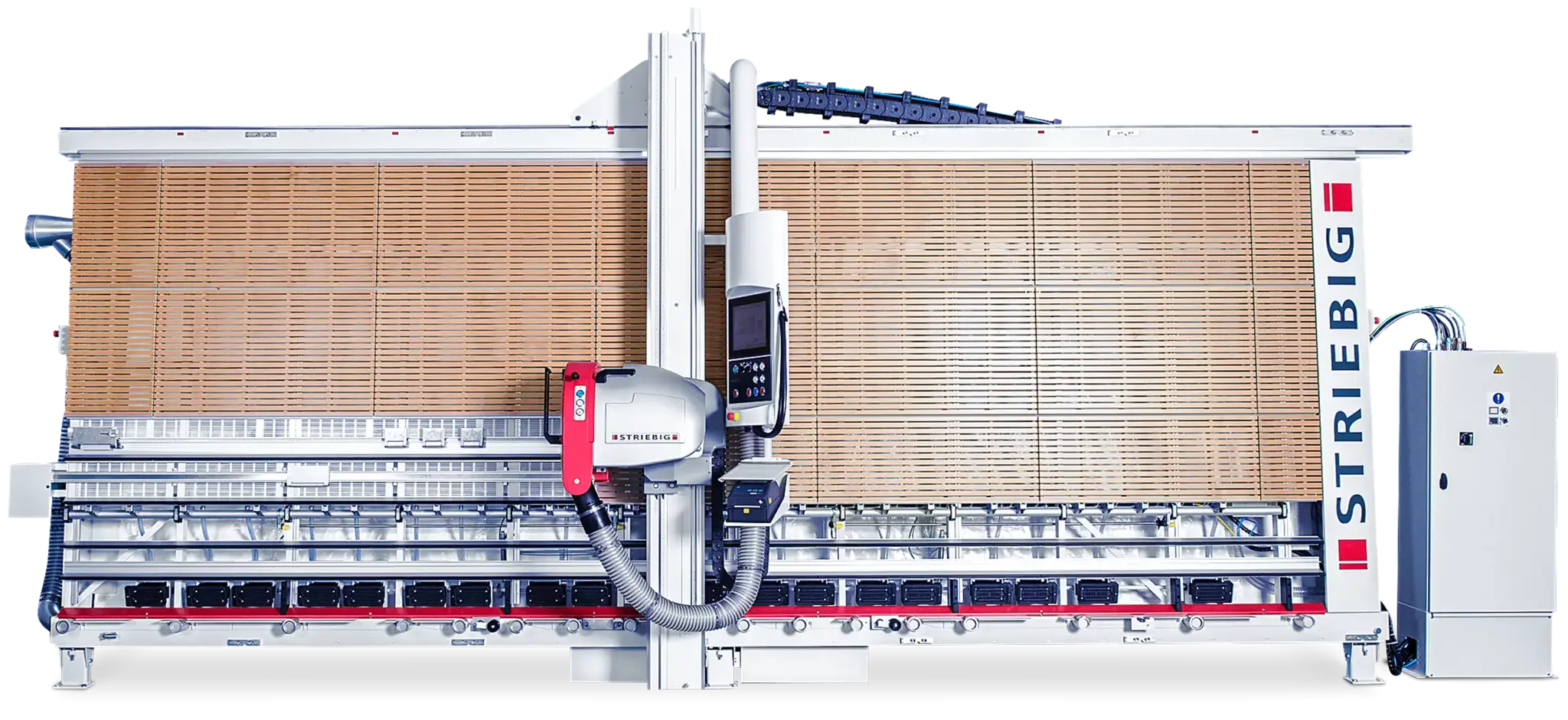

Premium automatic vertical panel saw.

All of the features and options of the Striebig Evolution, plus

- Automatic, variable speed (0.3-82 ft/min) travel

- EPS.Y auto- saw head positioning, including top of panel recognition and trimming, and repeat horizontal cuts

- Saw cycle (1/2 or full) selector, panel end sensor and start position memory

- Automatic saw beam positioning

- Configurable for screen-to-machine

Product Details

Advanced Automation and Features

The Control has a higher degree of automation and is equipped with additional options. Just as the Evolution is the world’s most advanced manual panel saw, the Striebig Control is the world’s most advanced (non-CNC) automatic traveling vertical panel saw. It incorporates all the features of the Evolution, including:

- Touch screen

- Full wood back support

- Digital measuring

- Automated locking and pivoting of the saw head

- Locking of the saw beam and rollers

In addition, the Control offers automatic travel of the saw in both axes, significantly enhancing productivity by reducing the need for manual movement.

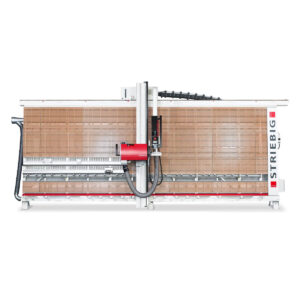

Enhanced Productivity

The Control improves productivity with:

- Variable and consistent feed speed: A panel end sensor stops the saw at the end of the sheet, not the machine.

- Memory for cut start points: The saw returns to the starting point of the cut, rather than traveling to the other end or top of the machine.

- Cycle selector switch: Allows the saw to wait at the end of a cut, giving the operator time to off-load the last piece before returning.

Increased Efficiency

The automatic nature of the Control allows the operator to off-load the last piece while the saw is returning, which is not possible with a manual saw where these are two separate functions. This also frees both hands to manage the piece being cut, especially useful for handling large, heavy pieces.

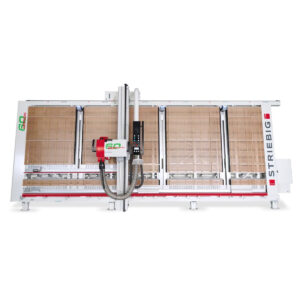

EPS.Y Feature for Precision

One of the most productive features of the Control is the EPS.Y electronic positioning system for horizontal cuts. This replaces the digital measuring system on the Evolution. The operator can:

- Enter the desired dimension of the rip cut (or choose it from a list)

- Confirm the dimension, prompting the saw head to position and lock itself automatically

This system is particularly useful for repeat rip cuts from the top of the sheet down, with a “repeat” icon for the last dimension cut. The EPS.Y feature can also locate the top of the panel and set the saw head for a predetermined trim cut.

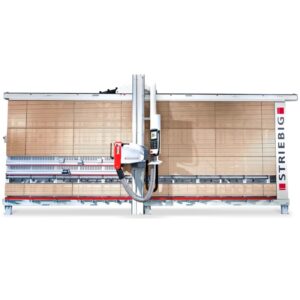

High-Volume Cutting and Space Efficiency

For those who perform a lot of rip cutting, such as closet fabricators or molding manufacturers, the Control offers a longer 6m saw frame with a 17’ cut capacity. This allows:

- Handling an 8’ sheet or stack of panels on both the left and right sides

- Achieving two cuts for one with each cycle by pressing the “go” button once

The operator can off-load the left pieces while the saw continues cutting on the right side, and off-load the right side while the saw returns. By touching the “repeat” icon, this process can be repeated almost completely automatically, making the Control incredibly productive in a fraction of the floor space required by a slider or beam saw.

Pre-Install Checklist

Striebig FAQs

Striebig Maintenance

View our recommended maintenance schedule

Striebig Troubleshooting

View our technical resources for Striebig owners