Description

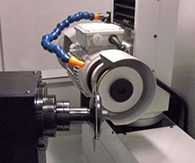

- 3Hp (6Hp option) Twin Spindle Grinding head allows for use of Cup wheel for high production or Periphery wheel for superior finish

- Automatically grind a wide variety of circular knives including HSS, Stainless or Carbide, top & bottom slitters, single & multiple bevels, counter knives, tissue knives

- Touchscreen CNC Controller programmable for roughing, finishing, and sparkout cycle with ability to save & recall programs

- Match grind program allows grinding of multiple knives to the same diameter.

- Variable knife rotation speed up to 200 RPM

- Variable Grinding wheel speed

- Automatic central lubrication system

- 2-axis CNC stepper motors with ballscrew drive and monorail slides for increased accuracy & durability

UTMA AC400-520-800 CNC Circular Knife Grinder with Periphery Grind

AC400 (for knives up to 15")

AC520 (for knives up to 20")

AC800 (for knives up to 31")

Standard Machine includes

AC520 (for knives up to 20")

AC800 (for knives up to 31")

Standard Machine includes

- 24 Gallon Paper filter coolant system for use in Oil or water based coolants

- Full cabin enclosure with machine lamp for safe & clean operation

- Electronic Handwheel for quick setup of both CNC Axis.

- Gear box pivots knife table to any bevel -90 to +90 degrees.

UTMA AC400-800 Optional Accessories

Quick change system

Automatic end of cycle indication with light

Coolant and Mist Extraction Systems

Standard Coolant System Specs To 35 micron, 5 GPM, 24 Gallon Tank

Tool Holding Machine uses an MT5 taper rotating head so an MT5 Arbor is required to mount knives on.

Because Circular knives vary significantly as to diameter, bore, bevel angle, and general configuration, Knife holding flanges are quoted at request. Generally Clamping Flanges run from $200 to $800.

Customers who are currently grinding circular knives on another machine, commonly find that they can use the clamping devices they already own.

Standard Coolant System Specs To 35 micron, 5 GPM, 24 Gallon Tank

- Automatic Paper roll filtration system To 35 micron, 13 GPM, 45 Gallon Tank

- Magnetic Separator for HSS - Can be used with standard system or auto paper roll system

- Double Centrifuge Mist extraction system for Oil coolants Required for full cabin machines, but may be supplied by customer

Tool Holding Machine uses an MT5 taper rotating head so an MT5 Arbor is required to mount knives on.

Because Circular knives vary significantly as to diameter, bore, bevel angle, and general configuration, Knife holding flanges are quoted at request. Generally Clamping Flanges run from $200 to $800.

Customers who are currently grinding circular knives on another machine, commonly find that they can use the clamping devices they already own.

Knife Diameters: 1 to 15, 20, or 31"

Maximum Stroke: Up to 150mm (6") (8" on AC800)

Grinding Motor: 3 HP (2.2Kw) 6HP option

Grinding Wheel Diameter: 150mm (6”)

Grinding Wheel Bore: 20mm

Voltage: 230/400V, 3Ph, 60Hz

Shipping Weight: 2210 lbs. (3,300 on AC800)

Maximum Stroke: Up to 150mm (6") (8" on AC800)

Grinding Motor: 3 HP (2.2Kw) 6HP option

Grinding Wheel Diameter: 150mm (6”)

Grinding Wheel Bore: 20mm

Voltage: 230/400V, 3Ph, 60Hz

Shipping Weight: 2210 lbs. (3,300 on AC800)

Oscillating periphery grind action provides highest quality edge necessary for tissue knives