Description

- Enclosed Cabin with coolant system

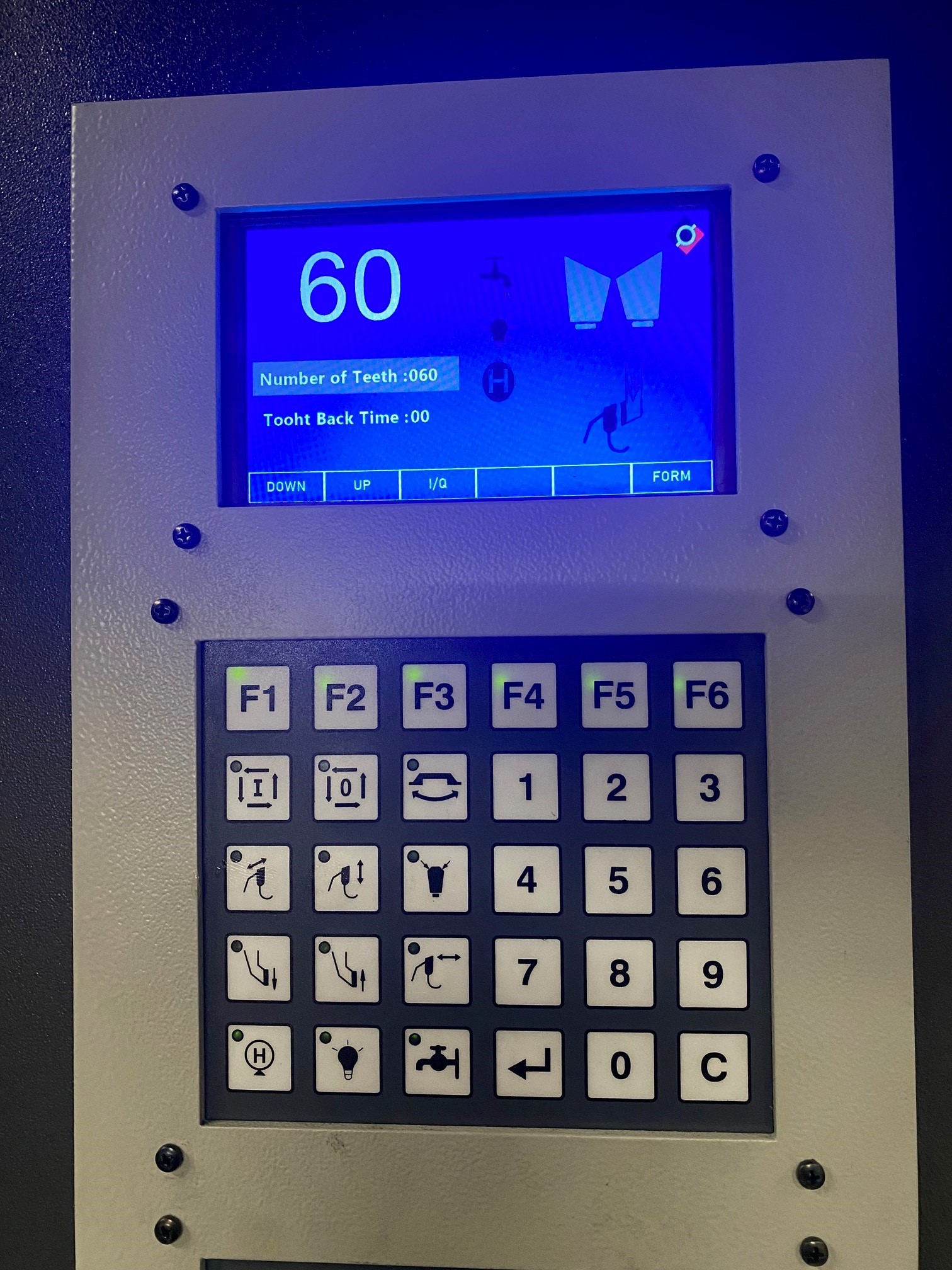

- Intuitive Controls for Quick Learning Curve

- Internal Diagnostics for trouble shooting

- "Lift Off" Face and Top Grinding

- Alternating Shear Face Grinding in One Revolution

- Hydraulic Saw Blade Clamp Rigidly Supports Blade During Grinding

- Independently Variable Grinding Speed Forward and Back

- Top Grinding of All Common Tooth Configurations

- Optional Hollow Grinding

The uniMAX-750 automatic grinding and sharpening machine is ideal for the smaller shop as its first automatic machine, for the mid sized shop as a dedicated face grinder or added topping capacity. Manufactured in Europe, the machine conforms to a high standard of quality while remaining fairly priced.

The automatic machine is capable of grinding all standard tooth shapes on carbide-tipped circular saw blades up to 750 mm. (30") diameter for cutting wood, plastic and other materials.

The rigid machine base forms the basis of outstanding stability and excellent grinding results.

The full cabin enclosure keeps the workplace clean, reduces noise, and greatly improves your shop air quality. The graphical control panel is used to enter machining data, such as tooth shapes, number of teeth and pre-selections of grinding wheel directions. A diagnostic program allows for efficient and economical troubleshooting. The control panel is used to display the number of teeth remaining in the current cycle as well as several set up operations.

An automatic swivel mounted grinding head allows the uniMAX-750 to grind bevel angles of up to 45°.

As a result of the automatic grinding wheel lift off and rapid return of the grinding head grinding times are reduced to a minimum and multi-grit wheels can be used to improve finish quality. A hydraulically powered clamp holds saw blades rigidly in position during the grinding operation.

The grinding head speed can be adjusted independently in both directions allowing the operator to minimize cycle time while maintaining superior edge finish quality.

Precision grinding for a wide variety of tooth shapes. A geared motor allows the operator to switch-over from top to face grinding in less than 2 minutes.

uniMAX-750 Hydraulic - For Circular Saw Blades

- Flood Coolant System

- High Intensity Machine Lamp

- Tooth Counter for end of cycle notification

- Set of Saw Bushings for 5/8 shaft

- External Multi Tap Transformer for Voltage Stabilization

- Shear face grinding in one revolution

- Hollow face grinding option ensures systematic hollow tooth finish

- Face grinding of all common face geometries

- Top grinding of all common top geometries

Power Consumption: 2.75 Kw

Maximum Blade Thickness: .2" (5 mm.)

Tooth Pitch: 7 to 100 mm.

Grinding Speed: Variable up to 18 teeth/min.

Voltage Std.: 220V/440V/3ph/60Hz

Shipping Weight: 1,550 lbs. (700 kg.)